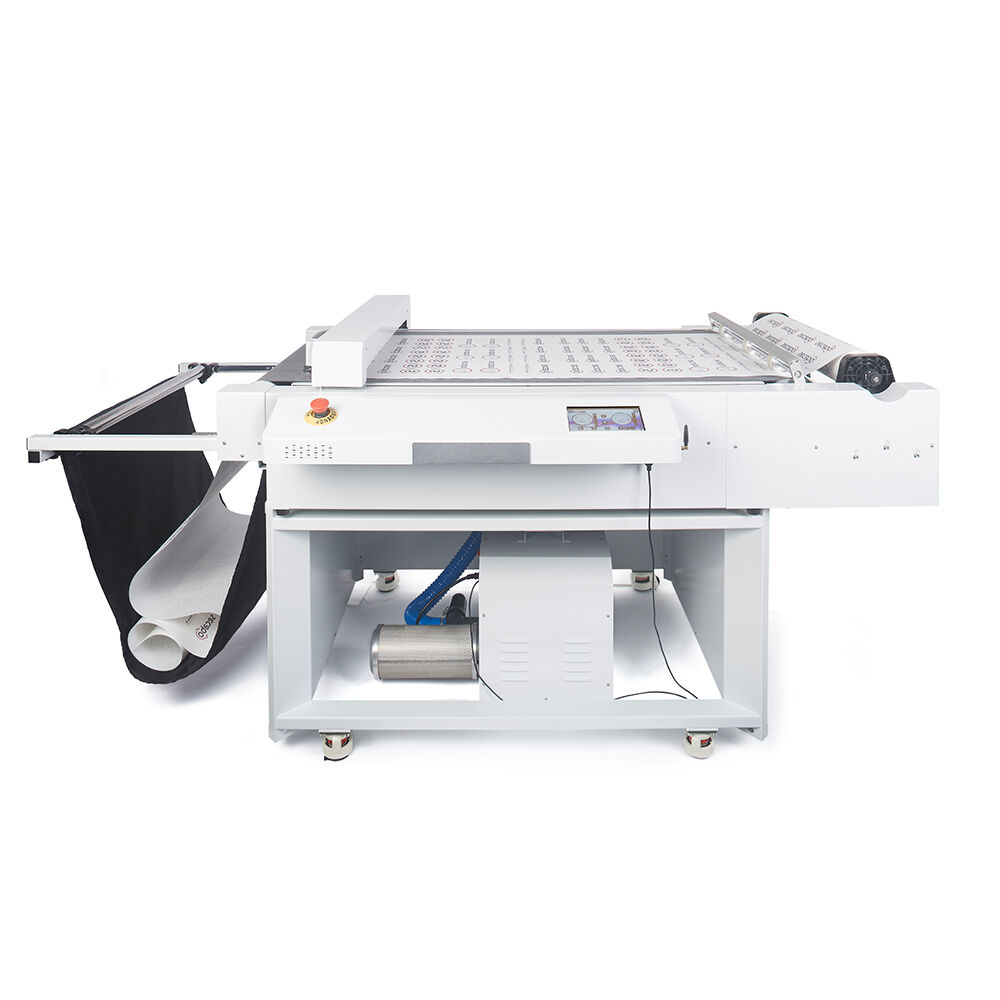

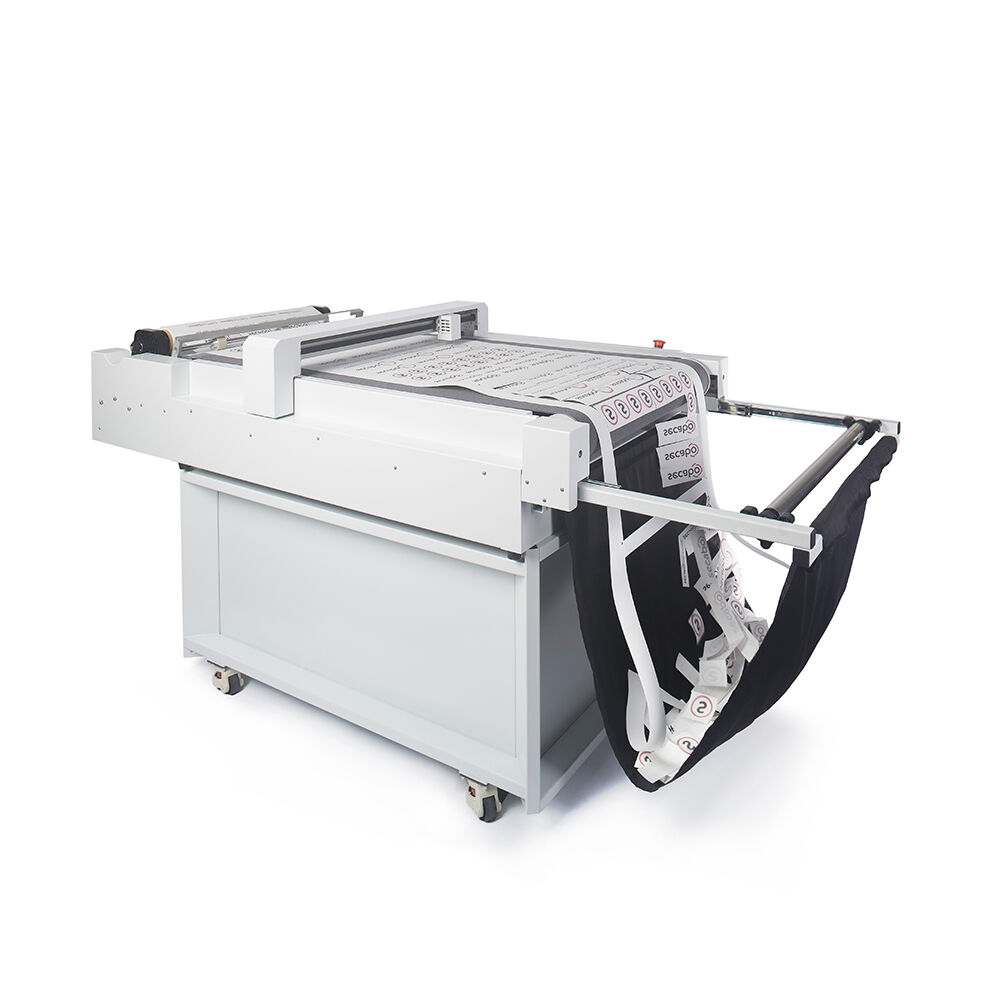

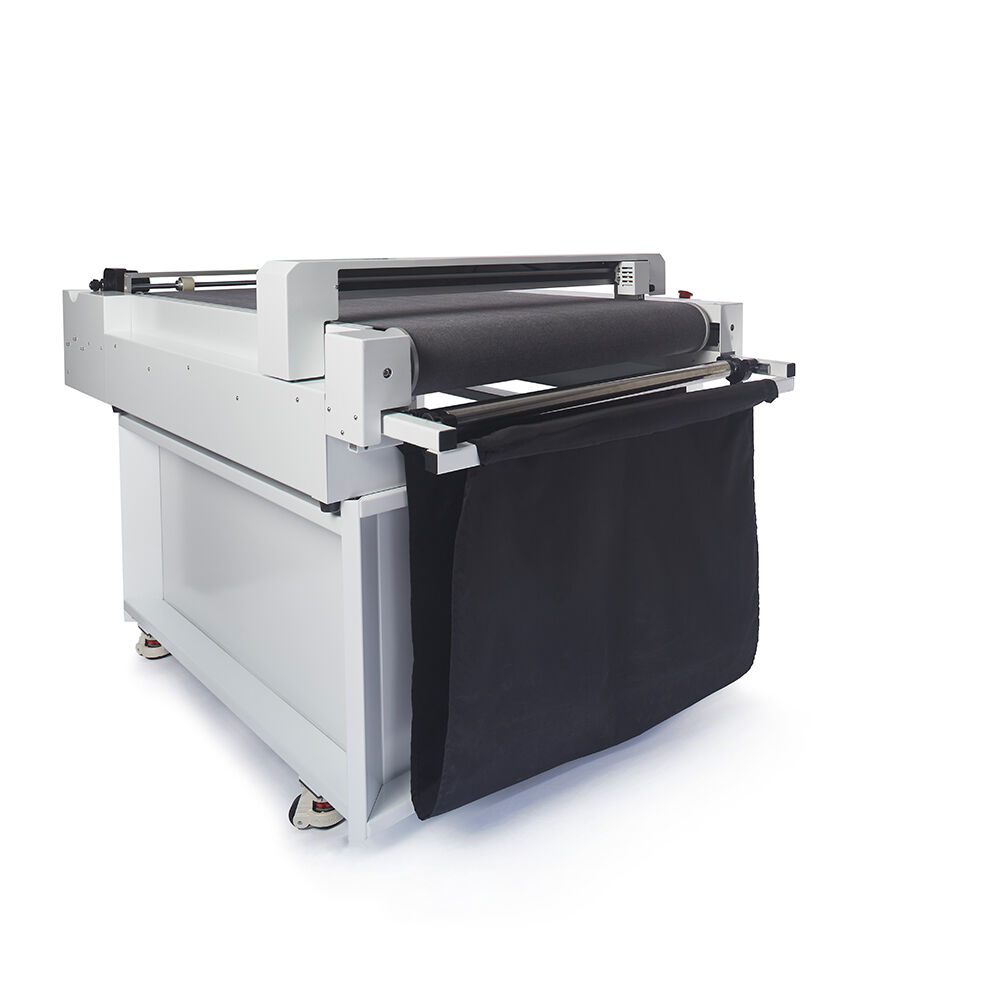

Secabo DTF Multicut Pro - Automatic roll flatbed plotter with conveyor system

|

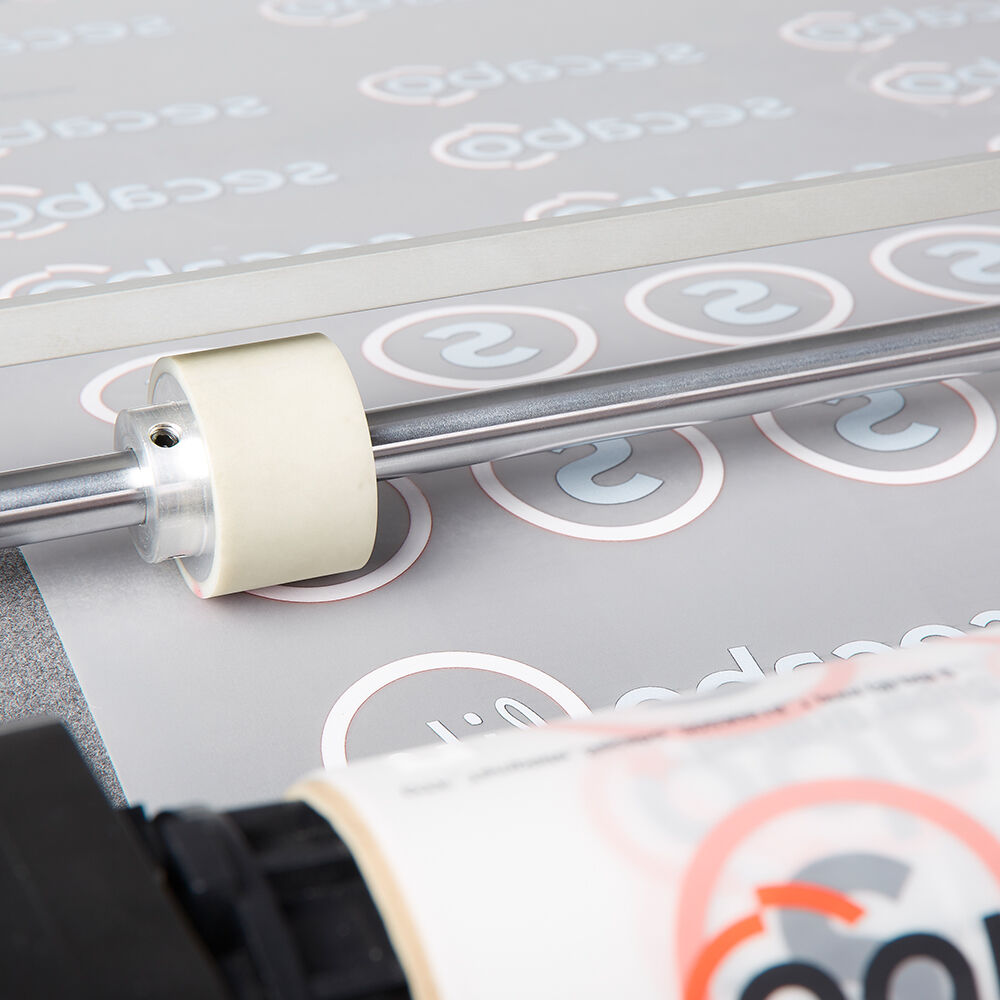

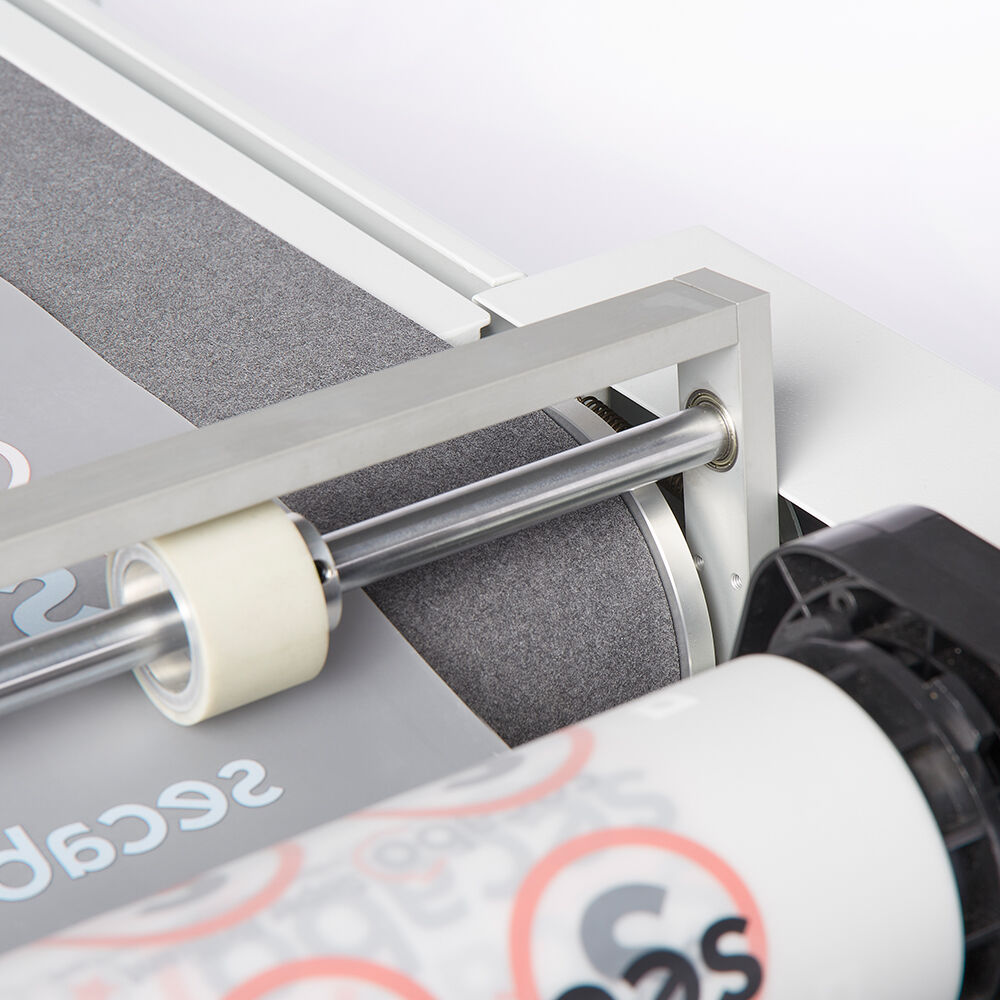

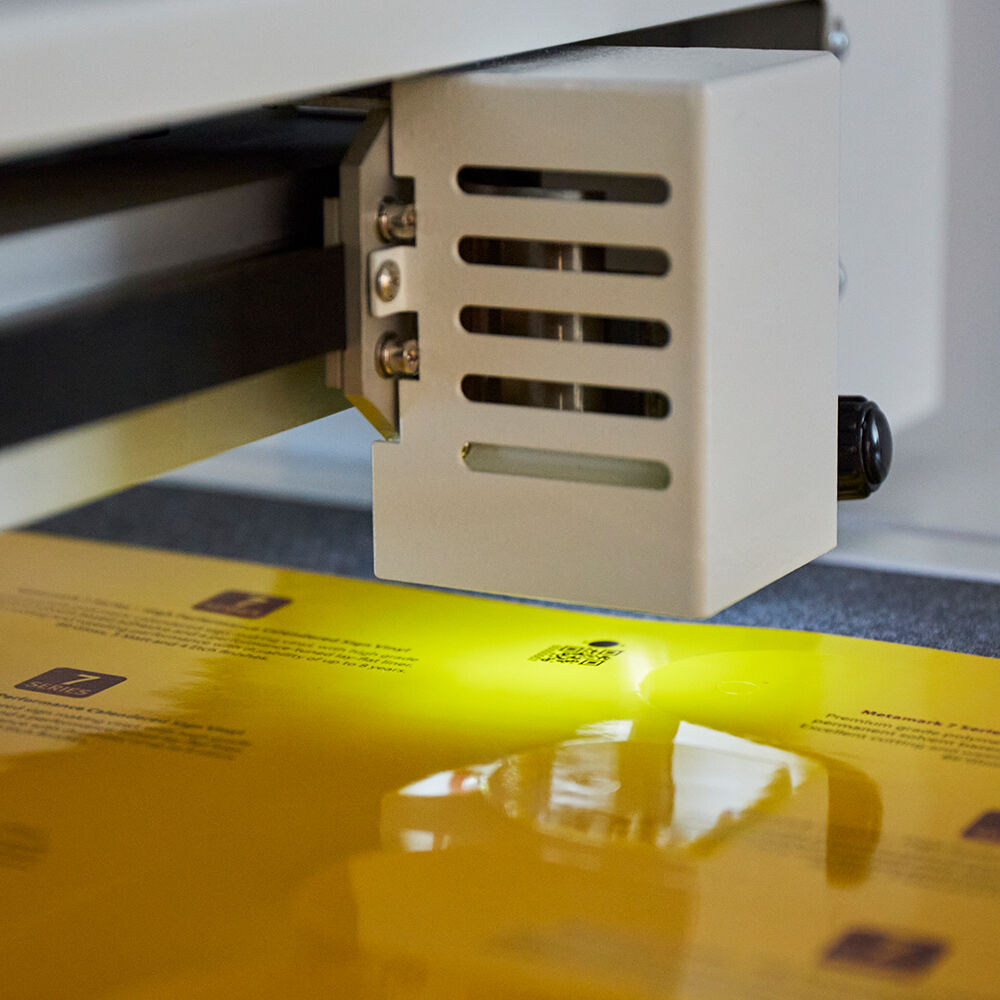

The Secabo DTF Multicut Pro is a high-precision flatbed plotter for the fully automatic processing of roll goods, DTF, sublimation and printed media. Thanks to the rotating felt belt conveyor system and integrated vacuum fixation, it enables precise contour cuts of any shape directly from the roll - the ideal solution for industrial DTF workflows. Find out how the Secabo DTF Multicut Pro can revolutionise your transfer production. With innovative functions, extensive software integration and flexible working methods, it offers the perfect solution for professional cutting of transfers, whether DTF transfers or sublimation. |

Buy now |

| Matrix-Cut | Perforation cut | Software integration | workflow | Technical data |

Different working methods

Whether 1000 identical transfers or complex arrangements for team sports or workwear.

The Multicut offers a seamless workflow for every application.

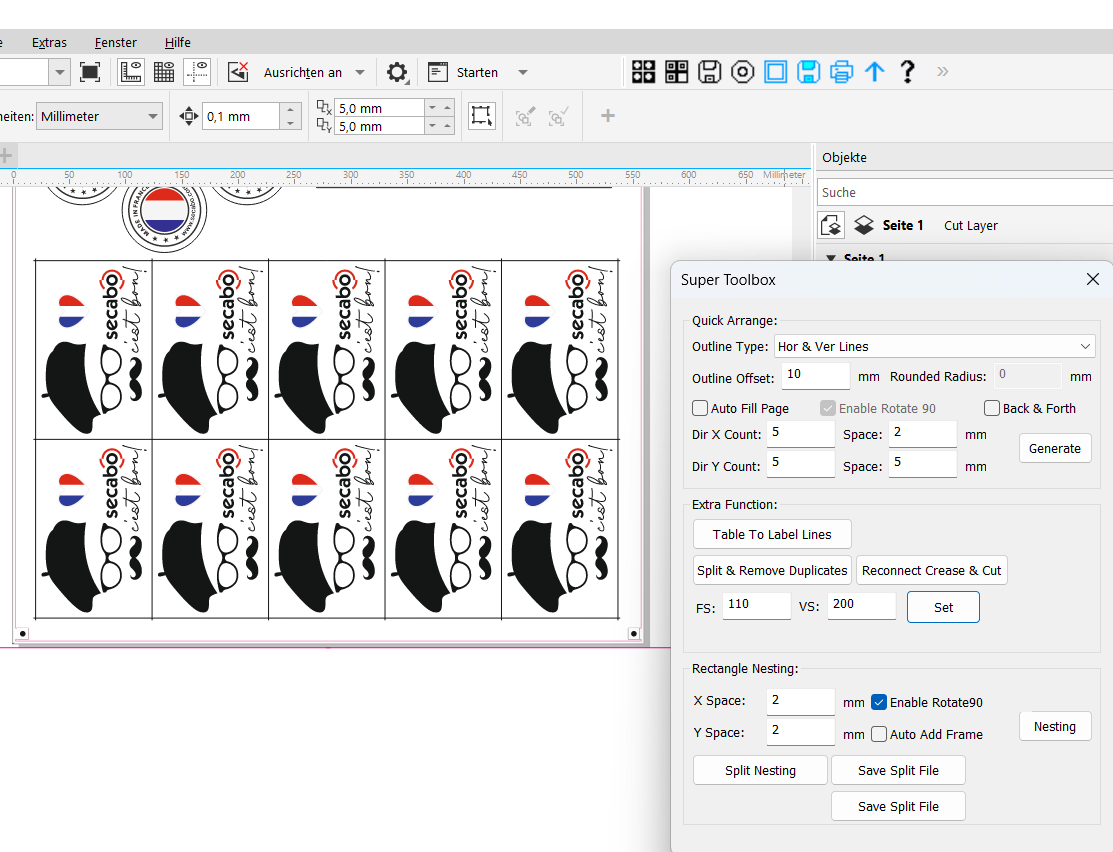

Matrix-Cut

Maximum efficiency for identical transfers Lightning fast, precise and perfect for large quantities:

The Matrix-Cut enables the automatic processing of many identical transfers in record time.

Thanks to horizontal and vertical cutting guidance, transfers are cut in an optimised grid - without manual intervention. This ensures even and efficient processing, ideal for series production with standardised layouts.

Perfect for the industrial production of promotional textiles where recurring motifs need to be processed quickly and without errors.

Perforation cutting

Cutting and sorting in one step

Thanks to the precise cutting and perforation functions of the Multicut Pro, the transfers not only remain perfectly cut, but also remain together exactly as they need to be applied later. This means no more tedious manual sorting - all transfers remain in the correct arrangement and can be processed directly.

Greater efficiency and error-free production

The combination of automated cutting, intelligent sorting and optimised workflow integration not only reduces production time, but also minimises sources of error. This makes the entire process significantly faster, more efficient and more economical - perfect for textile finishers who need to process large quantities of transfers while ensuring the highest quality.

Perfect for workwear and team shirts

Workwear, team shirts and sportswear in particular often require several transfers to be applied to a single textile. This often involves entire sets of tracksuits or workwear, where different names with individual numbers, sizes and colours have to be precisely assigned. Manual sorting and allocation are not only time-consuming, but also prone to errors.

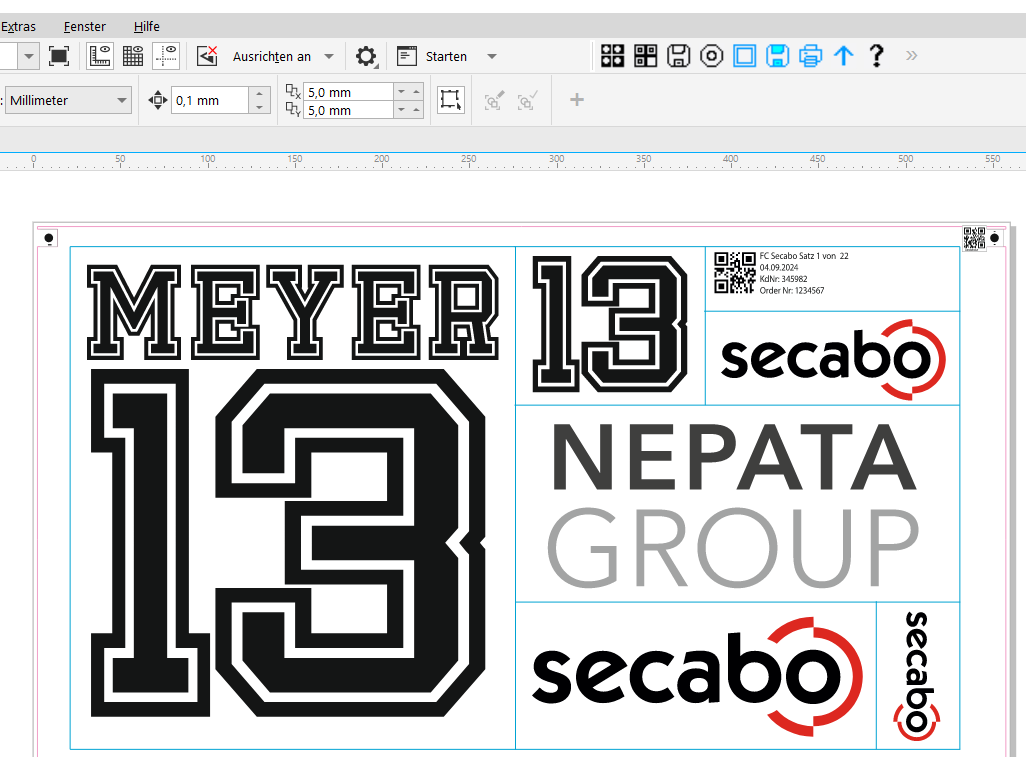

Create complex transfers effortlessly with templates

With the intelligent template function of the Secabo DTF Multicut Pro, creating and processing complex transfer layouts is child's play. The software makes it possible to use predefined templates for team and workwear labelling so that all transfers are automatically cut and grouped in the correct order. This ensures that all related elements - from names to numbers to sizes - are correctly assigned and ready for use.

Efficient & economical

With this advanced flatbed plotter, which automatically feeds material from the roll and cuts it precisely,

significantly reduces manual labour.

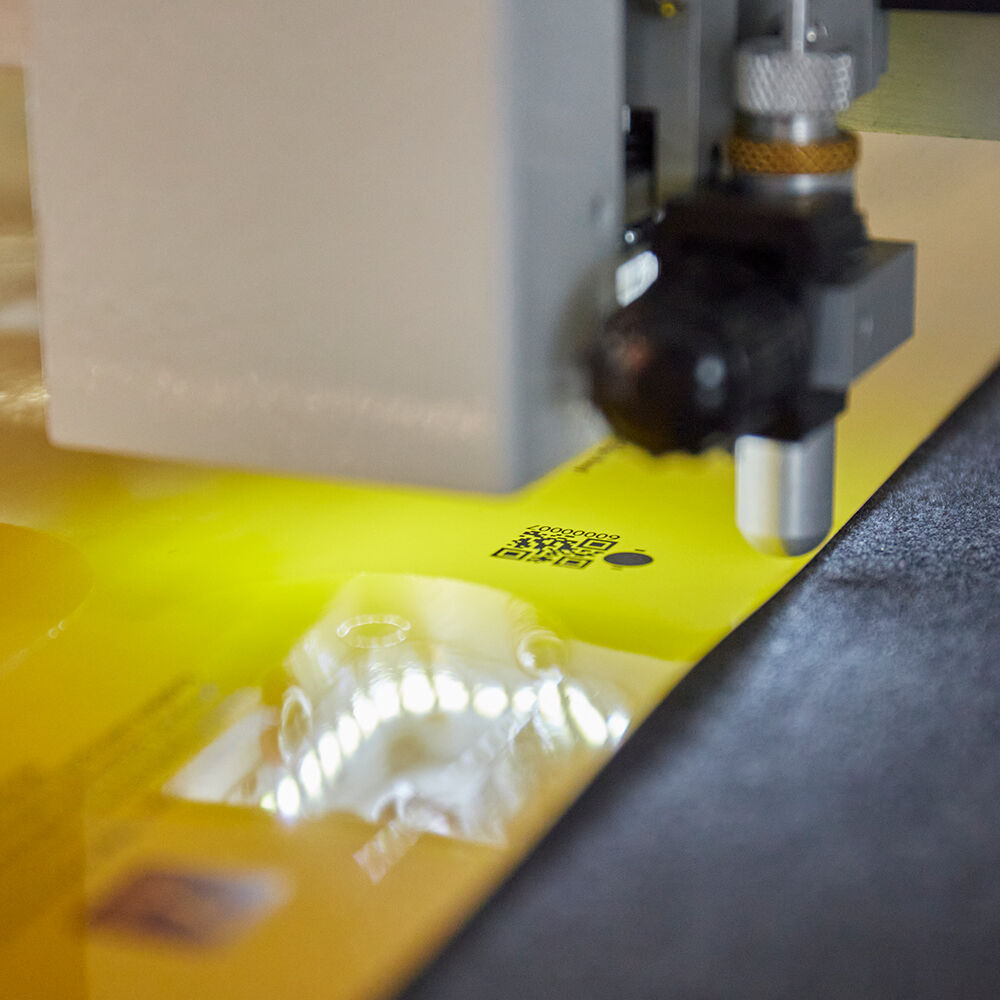

Automation with QR code system

The innovative QR code system enables automatic allocation of the cutting files to the respective prints. This further optimises the workflow and minimises errors.

Connectivity

The Multicut Pro offers numerous interfaces for maximum flexibility in the production environment:

- Ethernet - Stable wired network connection for high data security.

- WiFi - Wireless integration for flexible positioning and control.

- USB stick - Direct cutting without a network connection.

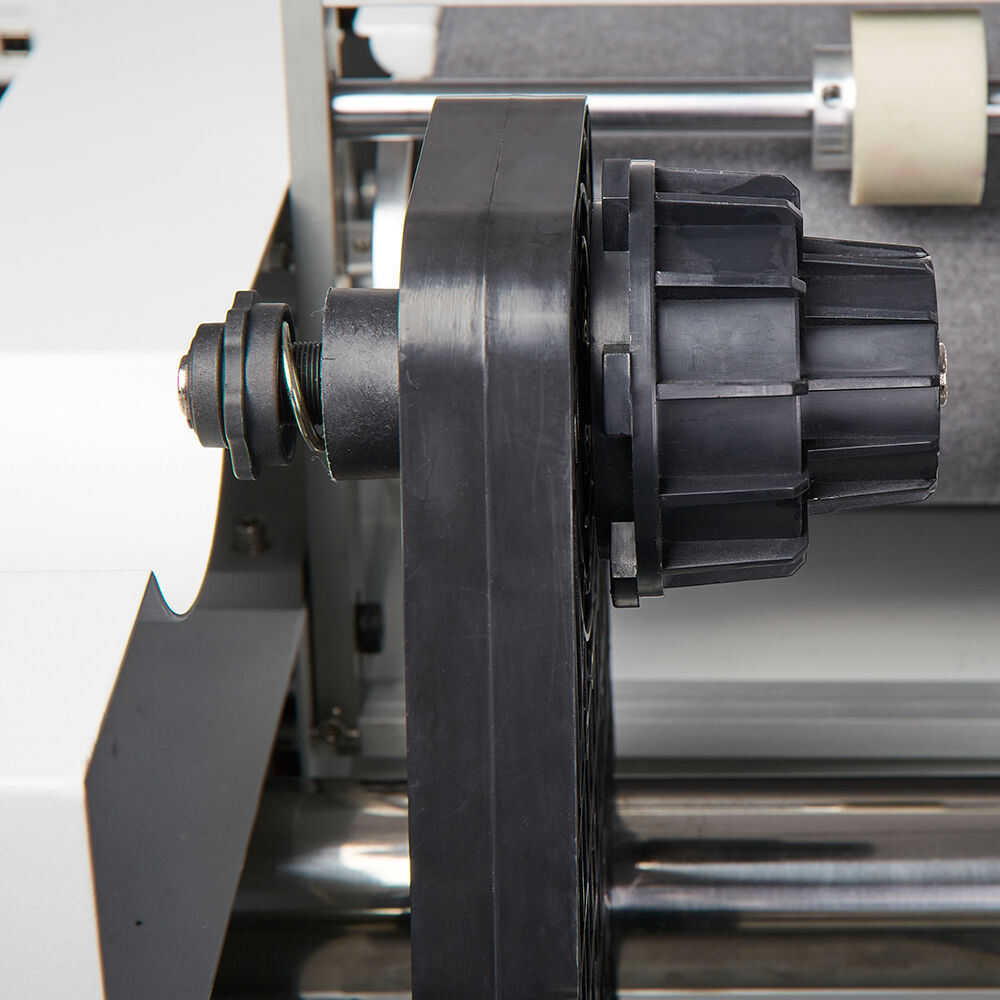

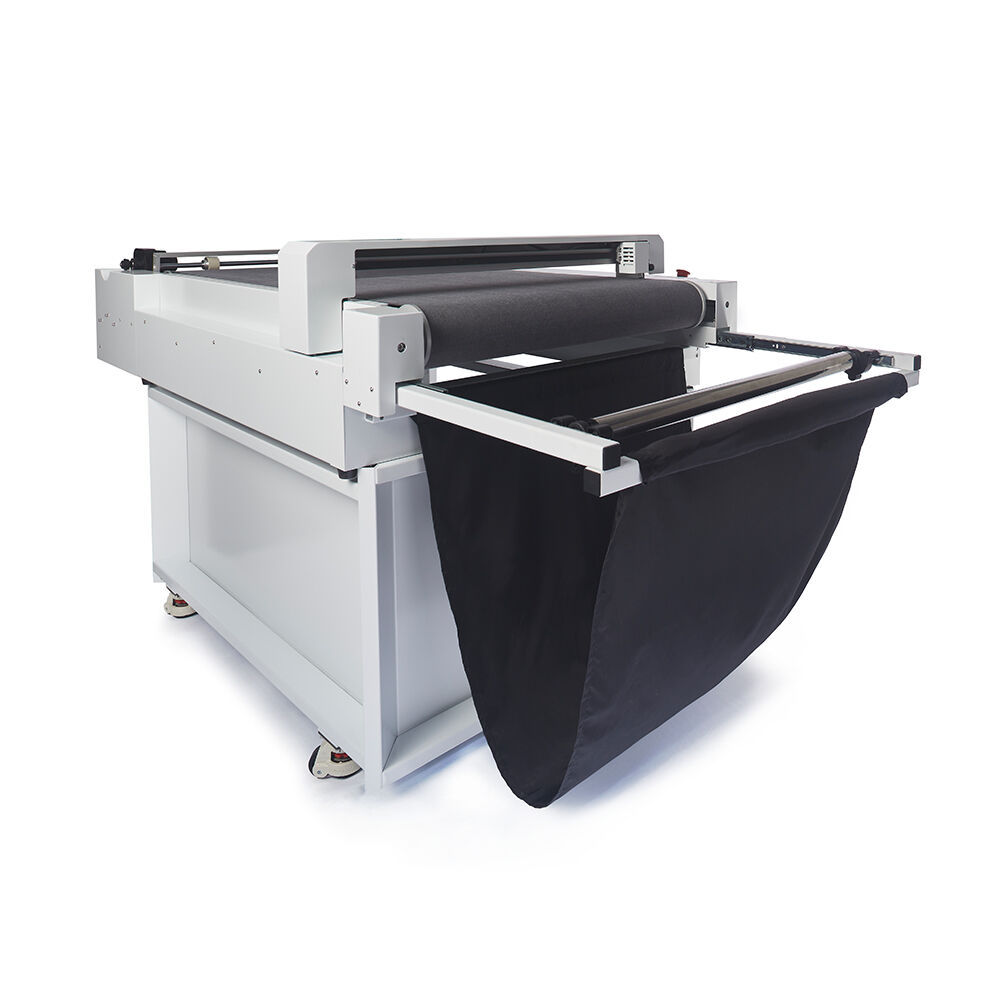

Conveyor belt for long prints

The Secabo DTF Multicut Pro is equipped with a conveyor belt that enables the cutting of long prints. It is ideal for cutting large orders with an extremely large number of motifs, large format productions for tents and awnings and continuous work processes.

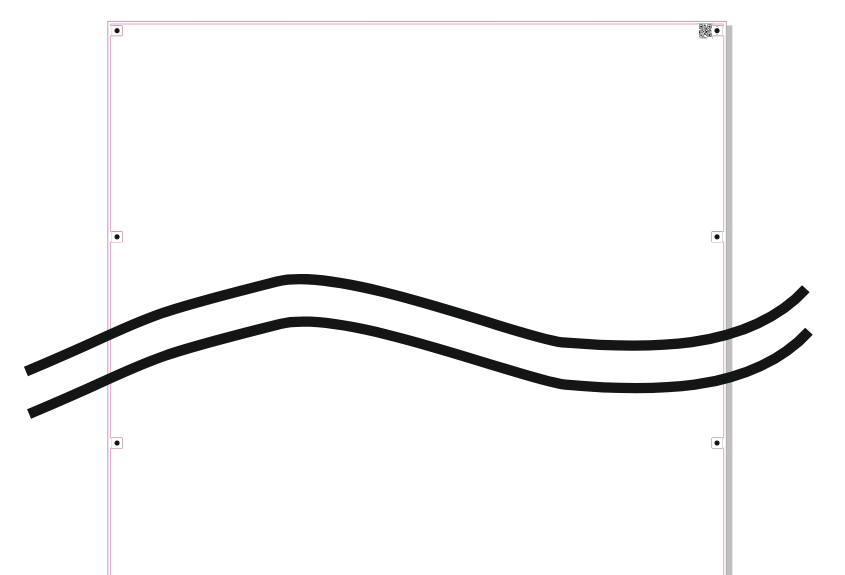

Continuous cutting with MultiMarks

The Secabo DTF Multicut Pro is equipped with a conveyor belt that enables the cutting of long prints. It is ideal for cutting large orders with an extremely large number of motifs, large format productions for tents and awnings and continuous work processes.

- A special mode that enables the cutting of prints several metres long.

- MultiMarks ensure exact positioning of the cuts over long distances and prevent misalignment.

- Ideal for large production jobs with consistent precision.

- The number and spacing of the markers can be customised

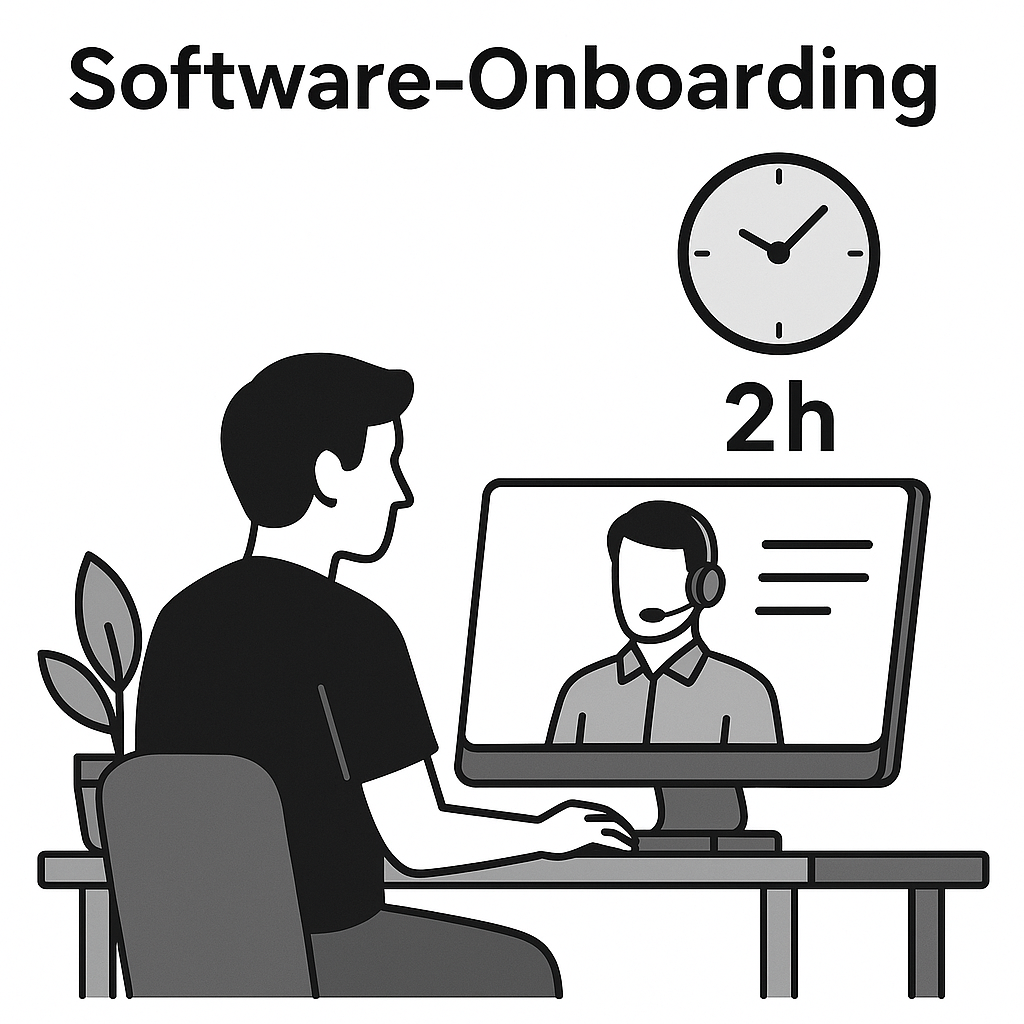

Software integrations

The Secabo DTF Multicut Pro offers versatile integration options for seamless integration into your existing production environment.

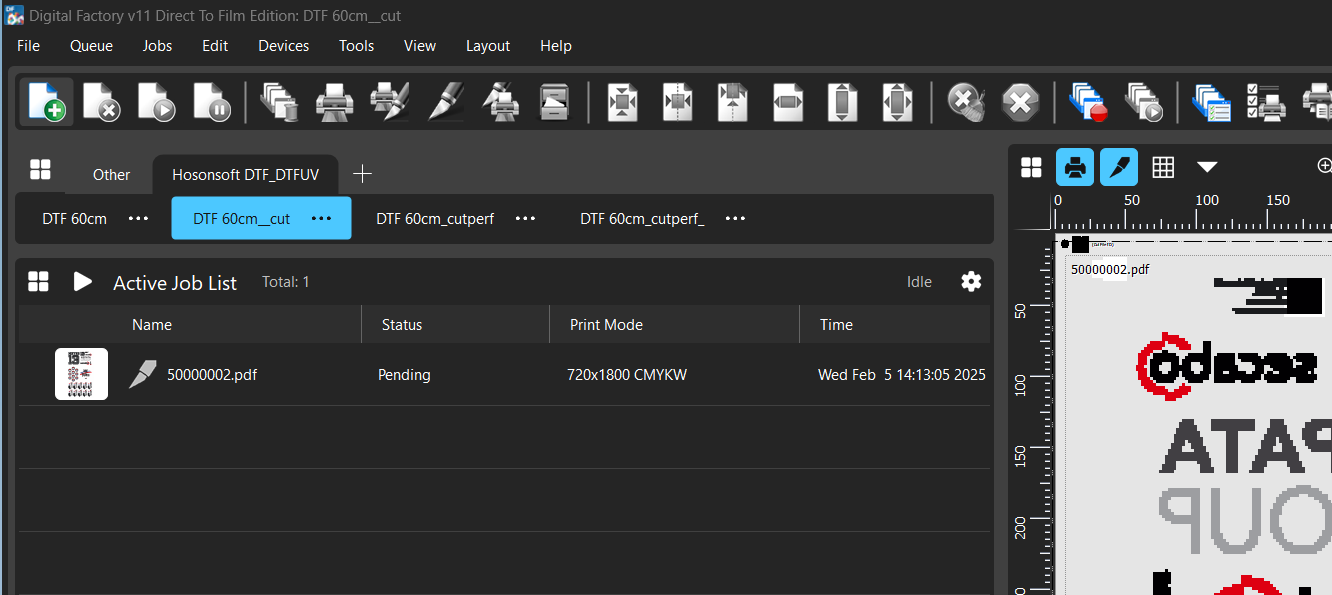

1 RIP software integration

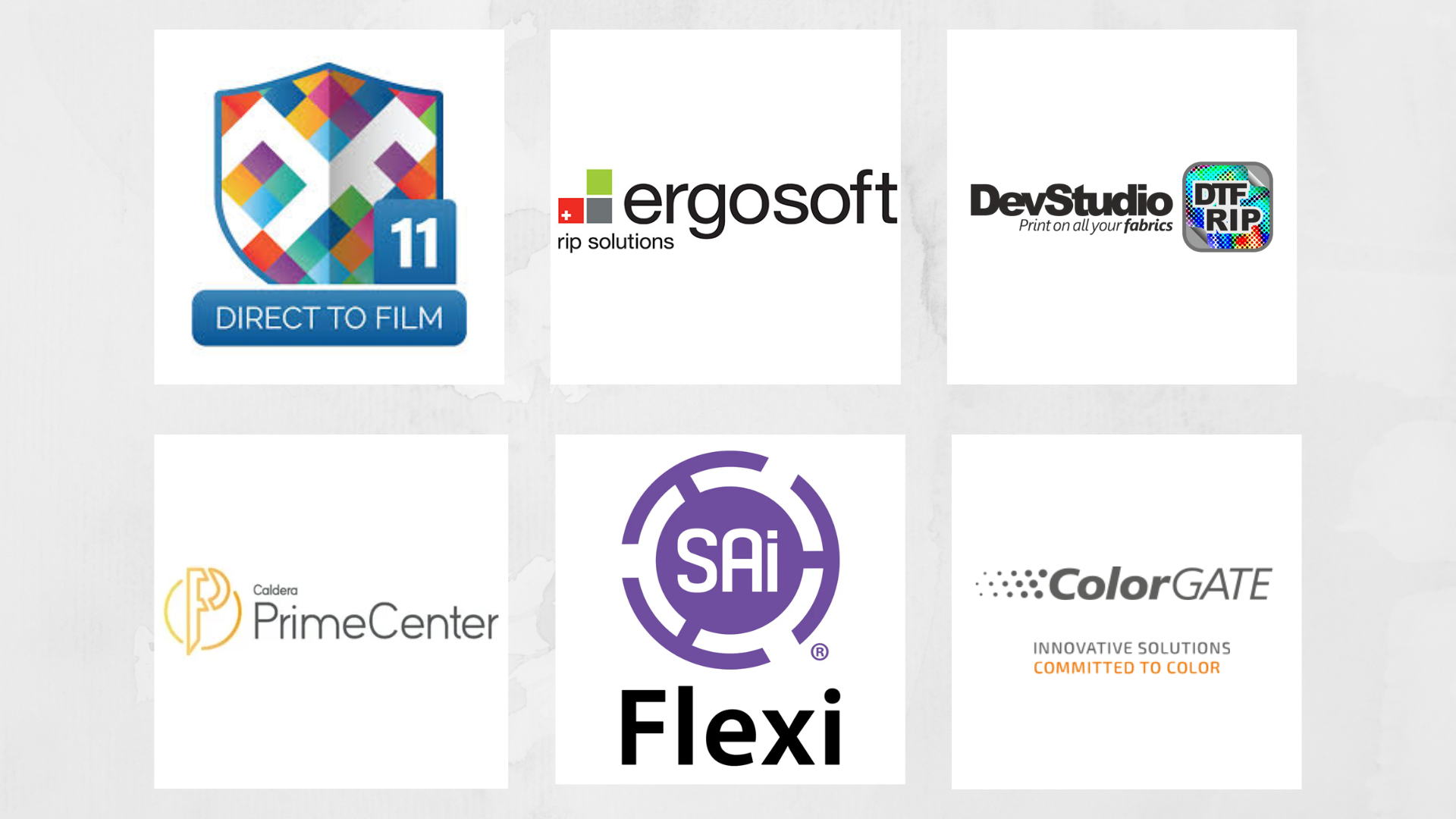

The machine is compatible with leading RIP software solutions:

Digital Factory (Fiery) - Optimised for excellent colour management and workflow automation.

Caldera - Powerful RIP solution for extensive production workflows.

Ergosoft - RIP software specially developed for textile printing for maximum precision.

2. plug-in integration

Plug-ins are available for direct control from graphics programmes:

CorelDraw - Simple creation of cutting lines and layouts with extensive productivity functions.

Adobe Illustrator - Automated creation of cutting contours and nesting of designs.

3 Caldera PrimeCenter

PrimeCenter enables optimum preparation of print files and precise automatic nesting for maximum material savings and efficiency.

Workflow ...

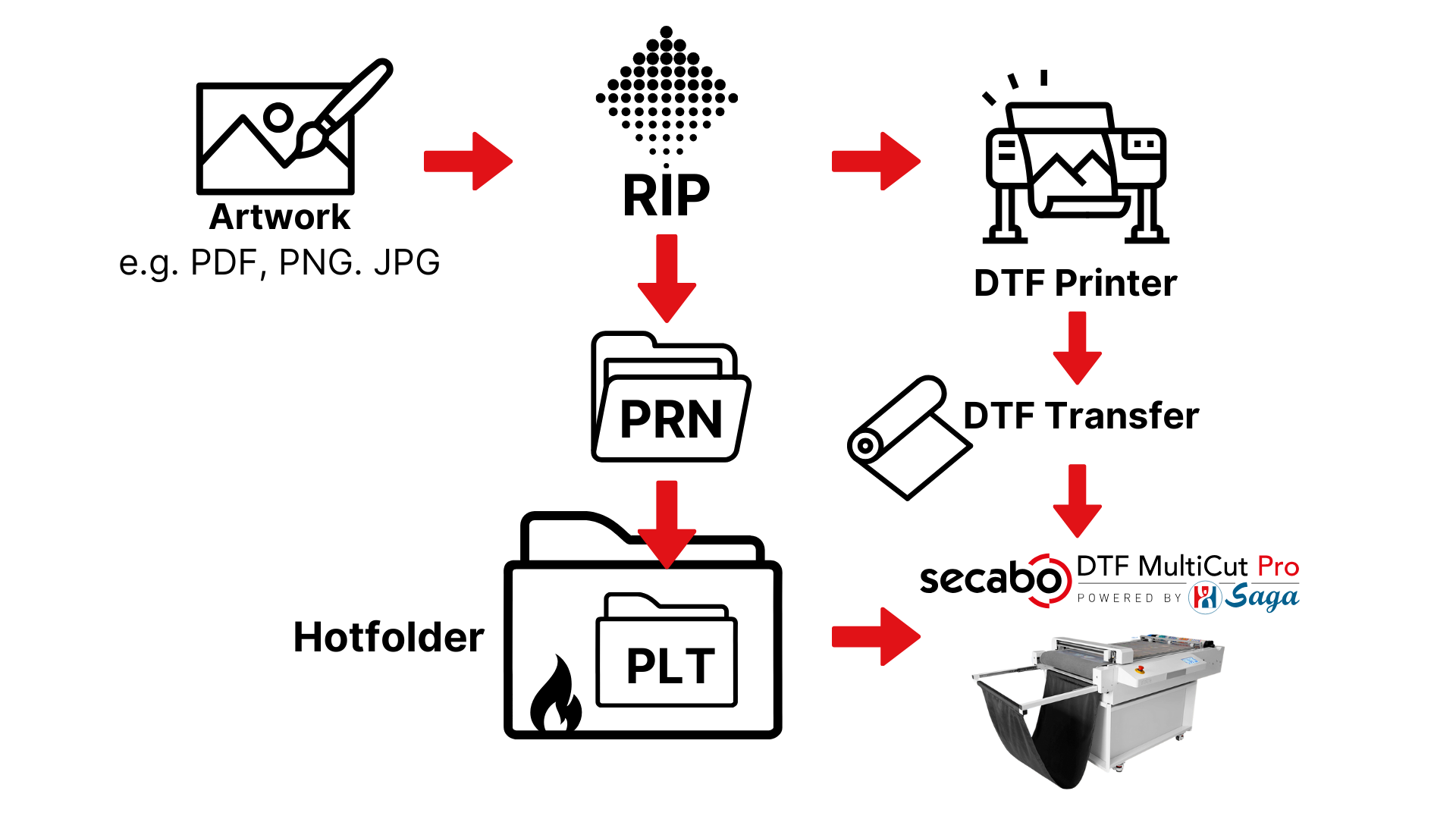

Workflow 1: Artwork to RIP to Printer and Cutter Workflow

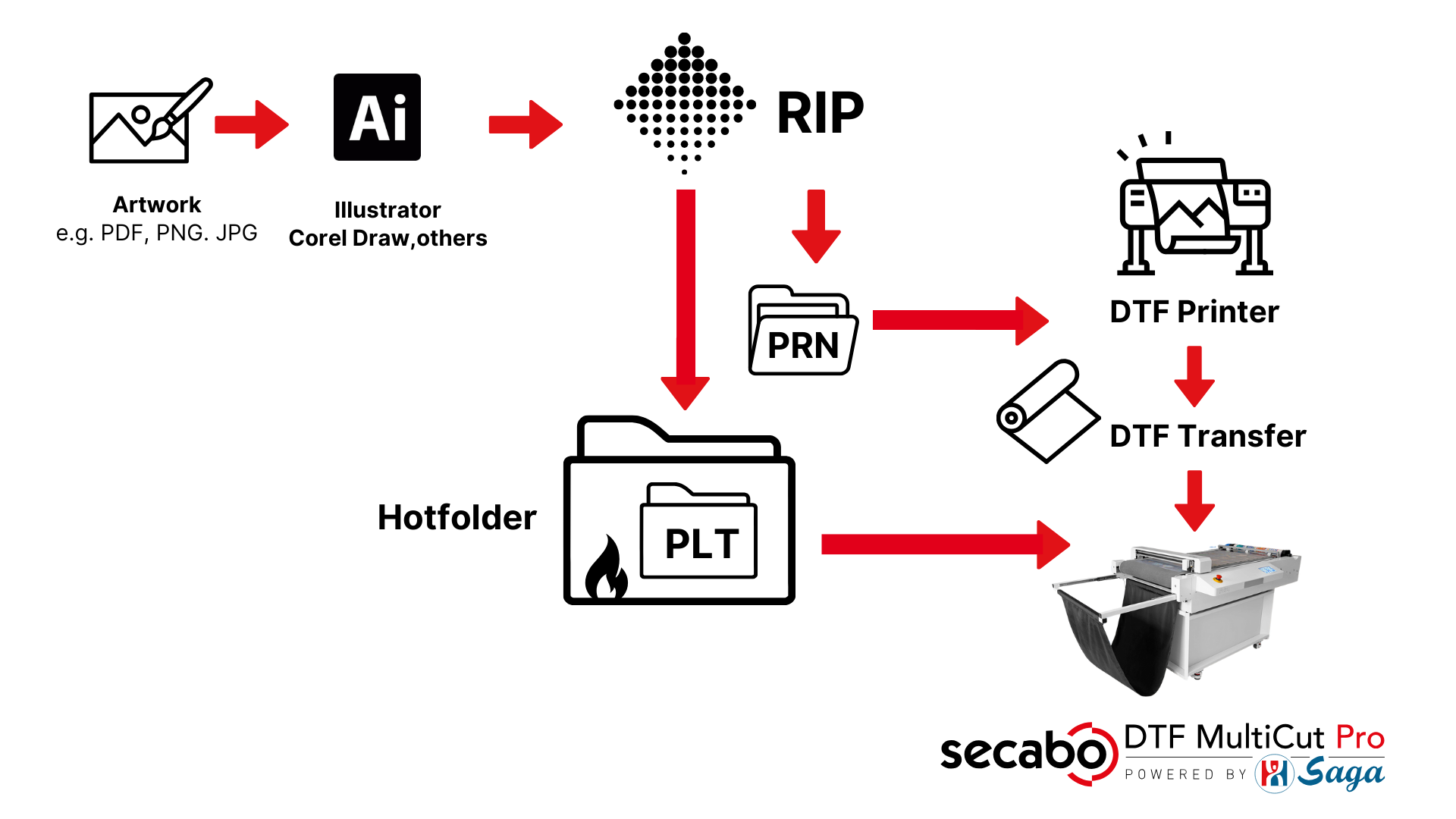

: Artwork to Adobe Illustrator/Corel Draw to Printer and Cutter Workflow

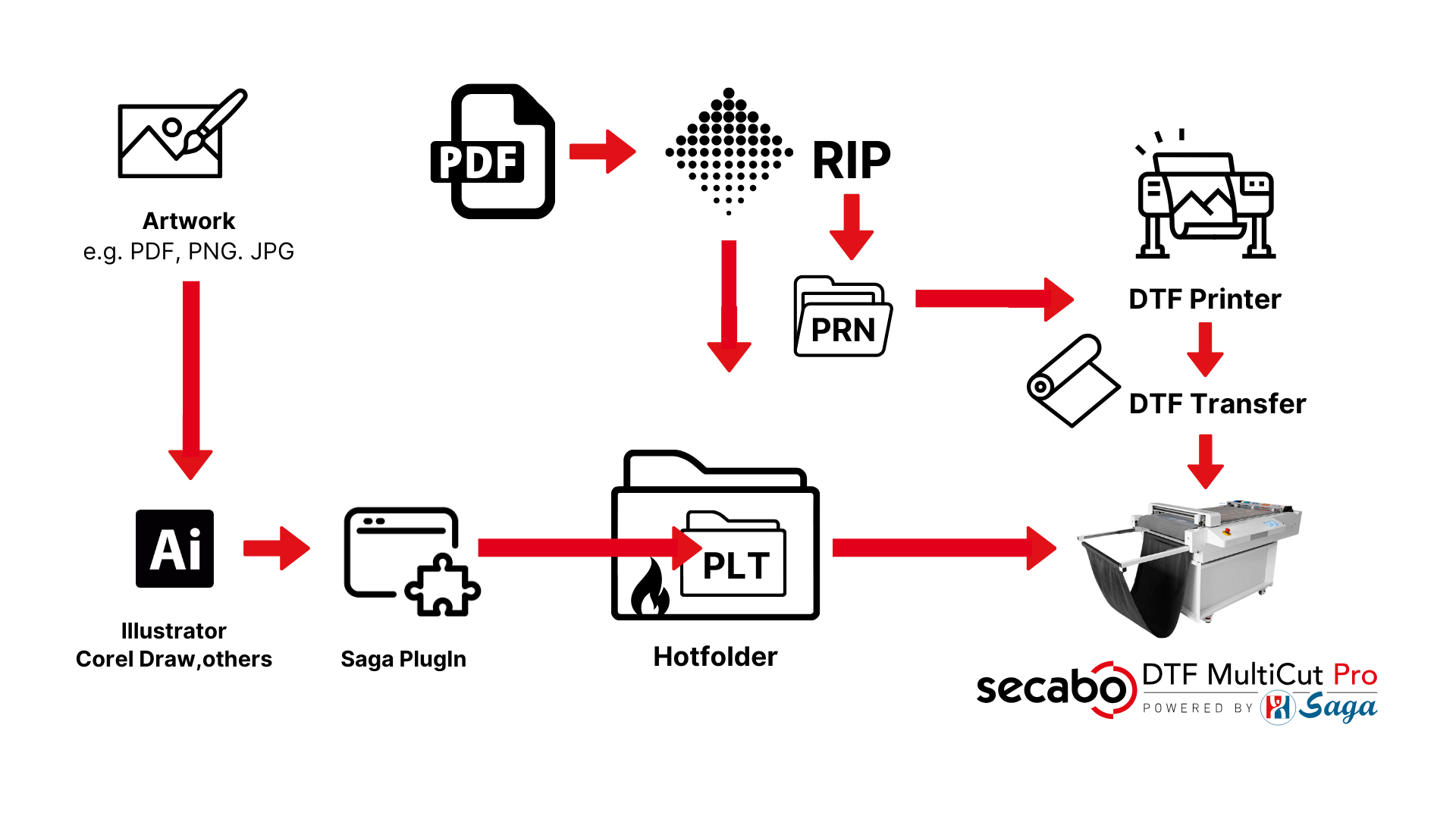

: Artwork to Adobe Illustrator/Corel Draw (Saga Plugin) to PDF and PLT

€14,875.00

Available in 89 days, delivery time 1-3 days

| Feature | motor details |

|---|---|

| Motor | X-servo motor; Y-servo motor |

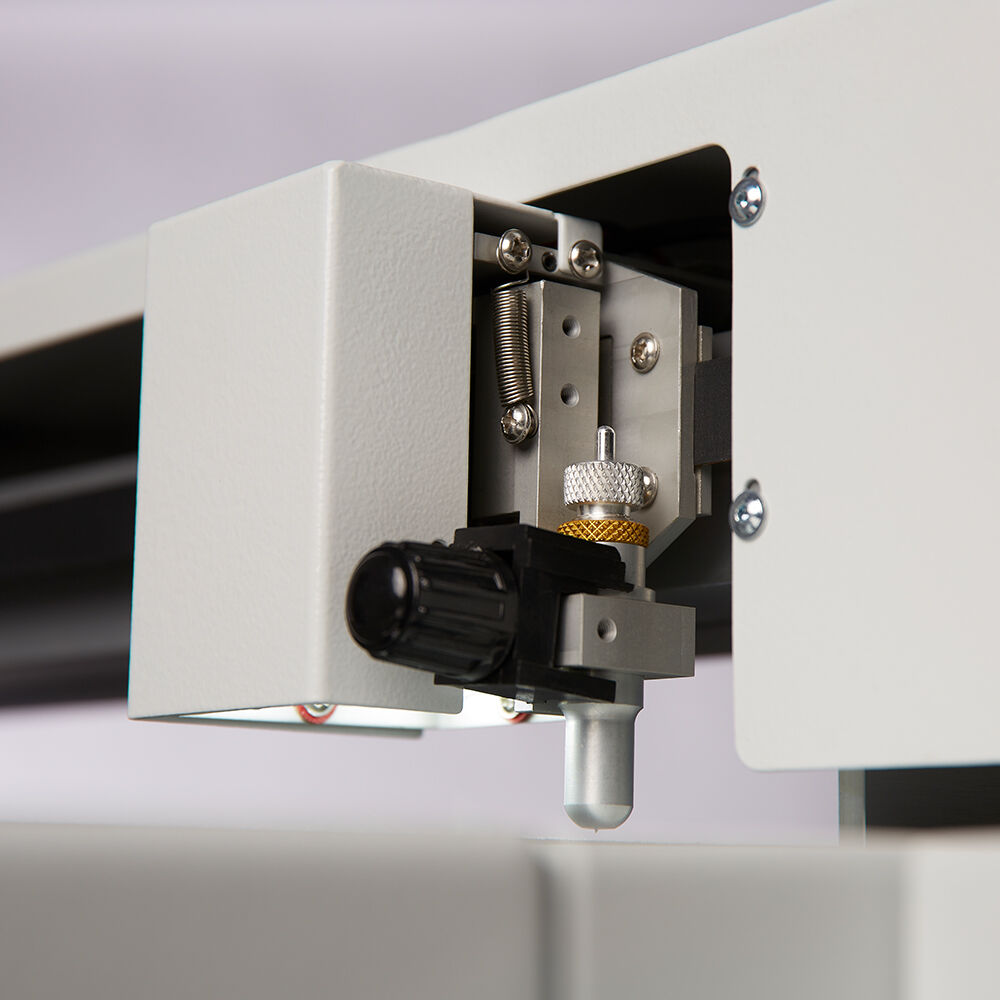

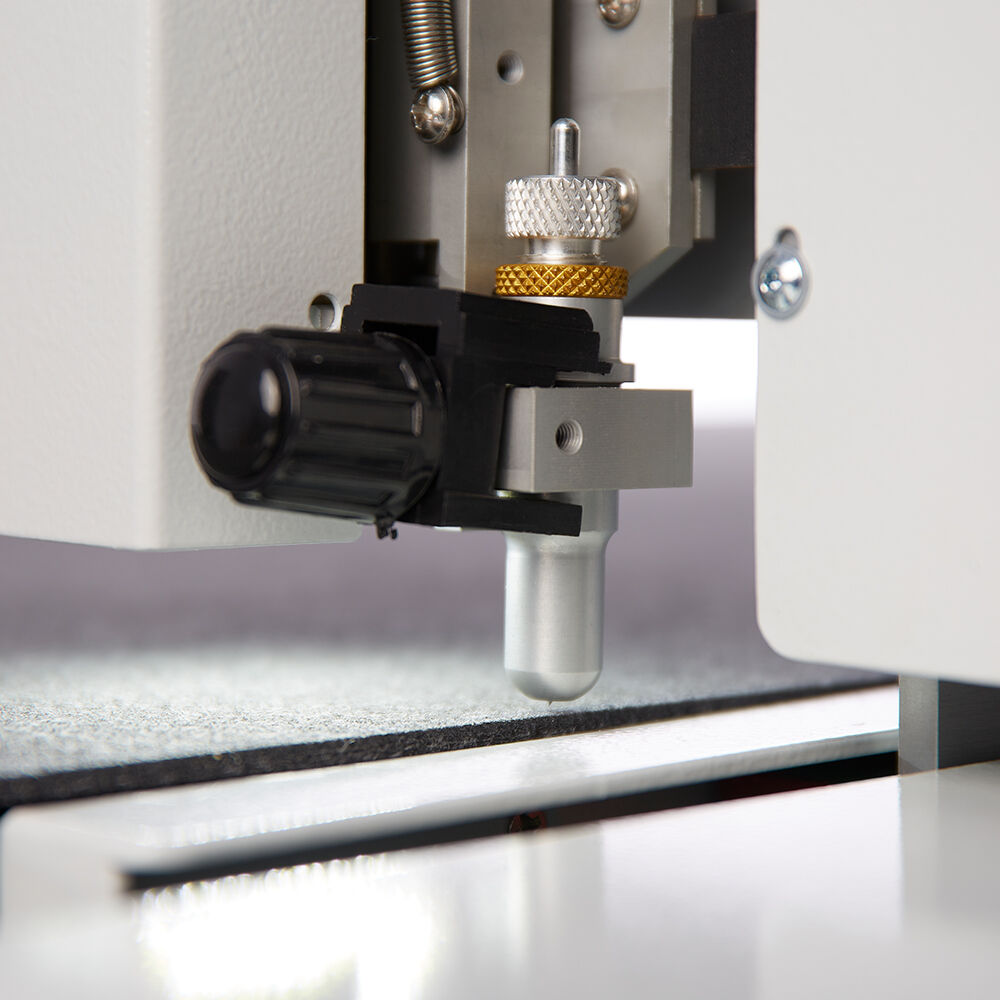

| Sensor | CCD camera |

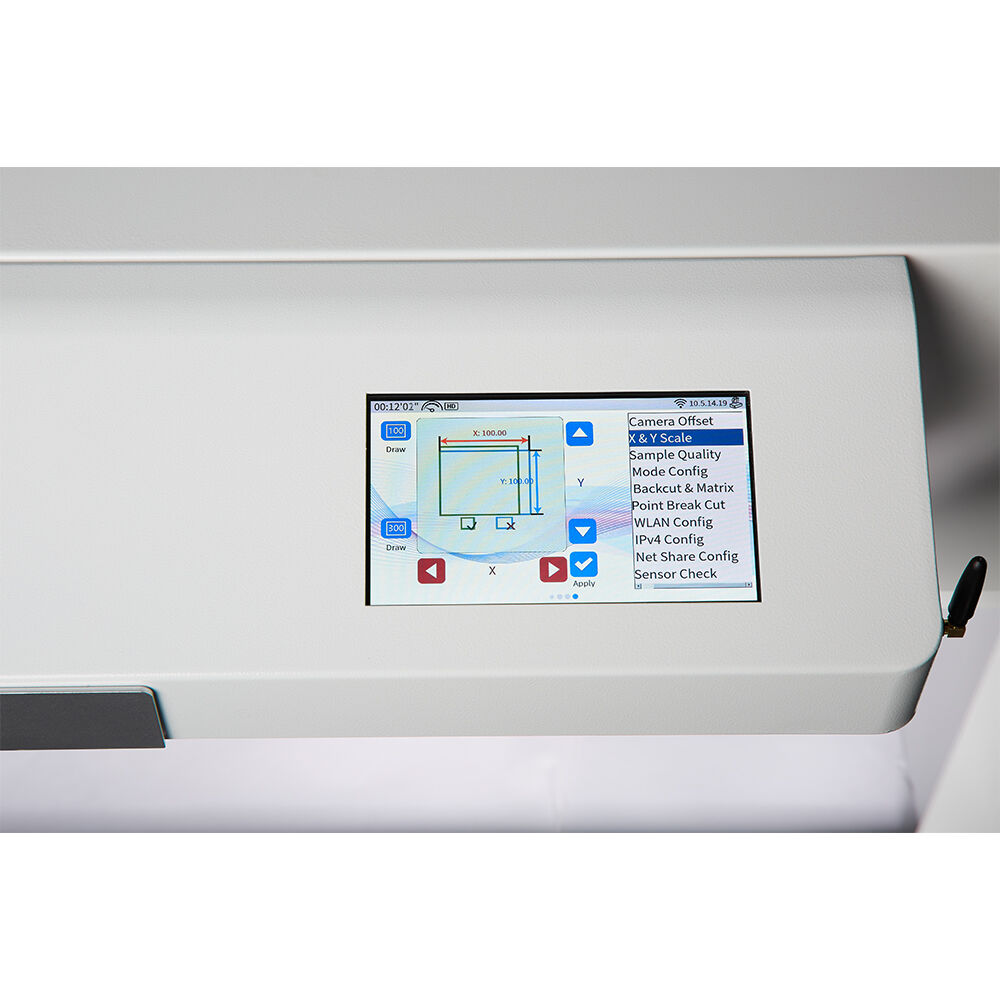

| Control unit | 7-inch touch screen |

| Number of tools | 1 |

| Tool type | Knife / pen |

| Media holding method | Vacuum suction function |

| Recognition code | Marking or QR code |

| Maximum cutting size | 640 mm × 880 mm |

| Scanning speed | approx. 5 seconds |

| Cutting speed | 10-700 mm/s |

| Cutting force | 0-750 g |

| Max. Material weight | approx. 250 g (depending on material) |

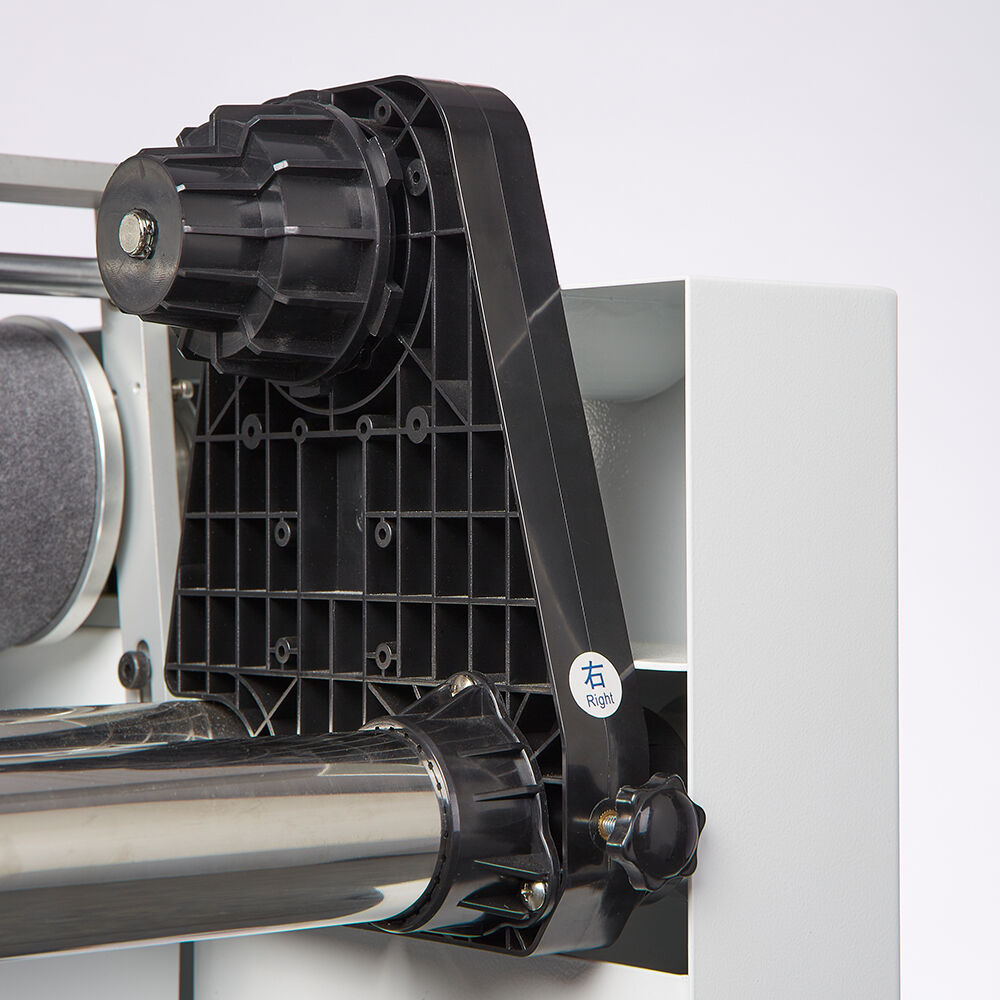

| Material feed | Automatic feed system |

| Max. Diameter of the material roll | 200 mm |

| Max. Width of the material roll | 600 mm |

| Feed speed | Adjustable |

| Minimum character height | approx. 10 mm² (depending on material & graphics) |

| Internal memory | Save files directly in the machine |

| Mechanical resolution | 0.02 mm |

| Programmable resolution | HPGL 0.025 mm |

| Repeat accuracy | ≤0.05 mm |

| Usable materials | Vinyl, self-adhesive stickers, cardboard |

| Connections | USB, TCP, WiFi, USB stick, interface |

| Weight with packaging | 277.00 kg |

| Brand name | Secabo |

Operating instructions and information on the RIP software connection can be found in the Secabo Knowledge Base.