Pneumatic presses

Pneumatic presses are Heat Presses that automatically control the contact pressure using compressed air. They offer even, powerful pressure distribution and are ideal for high-volume productions for flock, flex, sublimation and DTF transfers. Their automatic operation simplifies the workflow and reduces physical strain. They are particularly suitable for professional and industrial applications.

Filter products

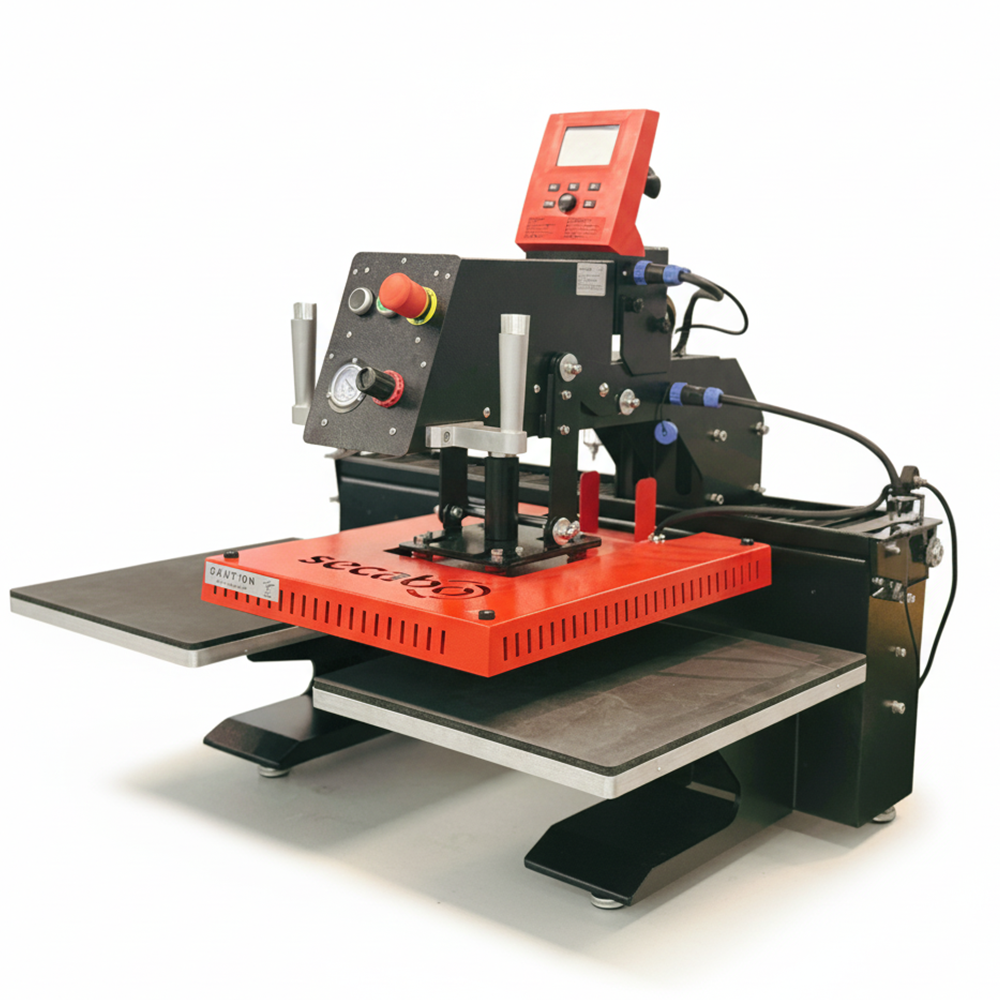

Secabo TPD7 Pneumatic double platen press

The new TPD7 Heat Press from Secabo is the perfect solution for large-format and extensive transfers with all common transfer processes in large print runs. This double-plate Heat Press works with compressed air, which ensures easy working with consistent and reproducible results. With a size of 40cm x 50cm each, the two work plates offer a particularly generous working area for conveniently aligning the transfer objects. Thanks to the vertical arrangement of the base plates, in contrast to the previous model, the exact positioning of the objects to be transferred is even easier. The convenient work surface on the exposed base plate increases the quality and precision of the transfers. The horizontally movable heating plate head can be easily aligned over the respective work plate, and the vertical contact pressure enables error-free transfer of a wide range of materials without offset effects.Special features of the TPD7 Heat Press:High heat output and heat capacity of the heating plate, good heat distributionEasily adjustable and reproducible pneumatic pressureExtensive range of accessories availableSafe working thanks to 2-hand operationSuitable for handling high order volumesPerfect press for DTF transfers and the DTF pressing processNote for exchangeable plates and adapters:Smaller interchangeable plates are available separately (8x12 cm, 12x38cm, 15x15cm, 20x30cm) and can only be mounted in combination with the Secabo interchangeable plate quick changer for TPD7 (art. no. 109.505.16)! For the optional Secabo base plate 38cm x 38cm (art. no. 109.505.40), the adapter for base plate and S.-W. Secabo TC5, TS7 (art. no. 109.505.30) is required in addition to the above-mentioned quick changer! If you also want to connect the original plate of the TPD7 to the quick coupler, you will need the adapter for base plate and S.-W. Secabo TC7, TPD7 (art. no. 109.505.31).

Secabo TP10 pneumatic Heat Press 80cm x 100cm

The newly developed TP10 from Secabo is the ideal Heat Press for professional finishers of large-format objects in particular: With an extra large work surface of 80cm x 100cm, this heat press model can be used to carry out heat transfers on large-format substrates such as flags, bed linen or textile room dividers. The base plate acts as a drawer element, which makes it easy to arrange the transfer objects and can be handled with little effort despite its size. The contact pressure of the TP10 Heat Press is generated with compressed air, which means easy working with consistent and reproducible results. The pneumatic heating platen head allows for error-free transferring of a wide variety of materials without offset effects or similar due to the vertical contact pressure. The Secabo TP10 Heat Press with a heating capacity of 5.1 kW is suitable for all known heat transfer processes and can therefore be used in almost all areas of transfer technology.

Secabo TPD7 SMART x Laser

Precision and efficiency for professional textile finishingThe Secabo TPD7 Smart x Laser is the flagship of Secabo's new generation of Heat Presses. This pneumatic double platen press has been specially developed to meet the requirements of modern production operations that demand maximum precision, flexibility and efficiency.With its integrated laser positioning, the TPD7 Smart x Laser enables exact placement of transfers - ideal for DTF transfers, flex and flock films and sublimation printing. The double work surface ensures a smooth production process: while one plate is being pressed, the other can already be reloaded.Modularity that pays offThe modular design of the TPD7 Smart x Laser offers clear advantages: Components such as the heating plate, base plate or controller can be easily replaced or extended as required. Accessories such as the thermobase or the quick-change system make the press customisable for a wide range of applications. This concept enables investment security, fast maintenance and lower storage costs.Intelligent control for efficient processesThe Secabo Smart Appis conveniently controlled via Bluetooth. This allows you to manage temperature, time and pressure digitally and save recurring jobs as presets. This optimises your workflow and reduces sources of error.Advantages of the Secabo TPD7 Smart x LaserPrecise laser positioning for error-free printing resultsPneumatic double plate press for consistent quality with high quantitiesModular design: Can be quickly and flexibly adapted to new requirementsControl via the Secabo Smart App for maximum controlGenerous working area - also suitable for thick textiles such as hoodies or jacketsTwo-hand safety operation and encapsulated guides for safe and low-maintenance use Successfully passedload test with 50,000 pressing cycles - developed for continuous useTypical areas of applicationProduction of DTF transfersFlex and flock applications in textile finishingSublimation printing on textilesSeries production of workwear, sportswear and merchandiseConclusionThe Secabo TPD7 Smart x Laser is the ideal choice for companies that value precision, efficiency and flexibility. With its modular design, intelligent control and proven Secabo quality, it offers a future-proof solution for all areas of professional textile finishing.

Secabo TPS7 SMART

The smart pneumatic transfer press for maximum efficiencyThe Secabo TPS7 Smart is the perfect solution for anyone who values efficiency, precision and flexibility. This pneumatic Heat Press impresses with its modular design and intelligent control via app, which makes the work process much easier.Whether DTF transfers, flex or flock foils or sublimation - with the TPS7 Smart, you can process a wide variety of materials quickly, reliably and with consistently high quality. The pneumatic contact pressure ensures reproducible results without manual effort, ideal for series production and professional textile finishing.Modularity meets intelligent controlThe TPS7 Smart is part of the proven Secabo modular system. Components such as heating plates, base plates or the controller are interchangeable and can be supplemented with accessories such as the thermobase or the quick-change system. This allows the press to be flexibly adapted to your production requirements.It is conveniently controlled via the Secabo Smart app via Bluetooth. This allows you to digitally control temperature, time and pressure and efficiently manage recurring jobs.Advantages of the Secabo TPS7 SmartPneumatic press head for even contact pressure without effortSmart app control for precise control and digital workflowsOptional drawer for convenient and safe workingModular design - compatible with the entire Secabo accessory systemTwo-hand safety operation for professional useRobust construction with encapsulated guides for minimal maintenanceTypical areas of applicationDTF transfer production of medium quantitiesFlex and flock finishing in advertising technologySublimation printing on textiles, bags and other materialsPersonalised series production in textile printingConclusionThe Secabo TPS7 Smart offers you a professional solution for flexible production requirements. With its intelligent control system, pneumatic system and modular expandability, it is the ideal press for growing businesses that prioritise efficiency and quality.

Secabo TPD7 SMART

Maximum efficiency and ease of use - without compromise.The Secabo TPD7 Smart is a high-performance double plate Heat Press with pneumatic control and digital smart control via Bluetooth. It has been specially developed for professional applications with high volumes - from DTF transfers and sublimation to flex and flock applications.The two work plates allow the printing and preparation processes to run in parallel. The TPD7 Smart therefore offers a continuous workflow with significantly increased productivity - ideal for high-throughput production environments.Modularity that pays offThe modular design of the TPD7 Smart offers clear advantages: Components such as the heating plate, base plate or controller can be easily replaced or extended as required. Accessories such as the thermobase or the quick-change system make the press customisable for a wide range of applications. This concept enables investment security, fast maintenance and lower storage costs.Intelligent control for efficient processesThe Secabo Smart App is conveniently controlled via Bluetooth. This allows you to manage temperature, time and pressure digitally and save recurring jobs as presets. This optimises your workflow and reduces sources of error.Advantages of the Secabo TPD7 Smart Pneumatic double plate press for efficient work in series productionSmart app control via Bluetooth for precise control of temperature and timeModular design - compatible with exchangeable plates, Energy Saver Kit, Thermobase and moreGenerous working area - also suitable for bulky textilesRobust construction with encapsulated guidesTwo-hand safety operation for maximum work safetyIdeal for DTF, flex, flock and sublimationTypical areas of applicationDTF transfer productionTextile finishing with flex or flock foilsSublimation on textiles, bags and moreSeries production of workwear, sportswear and merchandise itemsConclusionThe Secabo TPD7 Smart is the perfect solution for professional users looking for maximum productivity, convenience and flexibility - without any laser positioning, but with full power.

Secabo TPD7 PREMIUM automatic double platen press

Top performance with high contact pressure, impressive heating power and heat distribution: that is the claim of the new TPD7 PREMIUM Heat Press from Secabo. The pneumatic double-plate press impresses with automatic movement of the press head, versatile features and a modular design. Transfers with an extremely high contact pressure of 12kN at 10bar (600g/cm2 or 1.2t) can be carried out on the generously dimensioned base plates, each measuring 40cm x 50cm. Intelligent functions make the application convenient and efficient, including the pre-press function with adjustable pre-press time, separately adjustable times for both base plates and storable sets for times and temperature. The heating plate with a power consumption of 2.5 kW ensures a high heat capacity with professional temperature distribution. The easily adjustable, reproducible pneumatic pressure can be optimally adapted to all transfer objects. Users benefit from added flexibility thanks to easily interchangeable components and compatibility with Secabo's quick-change systems, exchangeable plates and membrane base plates. The TPD7 PREMIUM Heat Press from Secabo complies with German safety standards. The stable base supports an ergonomic working height. The foot switch supplied makes operating the press head child's play. Extremely high contact pressure of 12kN at 10bar (600g/cm2 or 1.2t)Automatic movement of the press headPre-press function with adjustable pre-press timeSeparately adjustable times for both base platesMemorisable sets of times and temperaturesExtremely high heat output and heat capacity of the heating plate, as well as professional heat distributionIncludes stable stand for an ergonomic working heightIncludes 2 cross lasers for easy object positioning