What are heat marks?

Heat marks when transferring textiles (also known as pressure marks, gloss marks or heat embossing) often occur during the textile finishing process.

Here is some basic information on this and how to avoid heat marks:Avoiding heat marks during textile transfer To avoid or at least minimise heat marks, the first step is to reduce the pressure and temperature and adjust the pressing times accordingly. Secabo offers special accessories to minimise heat marks.

Use of Secabo membrane heating plates

The Secabo membrane plate offers optimum pressure distribution thanks to its flexible surface and reduces direct punctual pressure on sensitive textiles, significantly minimising visible heat marks.

In addition, the membrane plate enables textiles with seams, buttons or zips to be pressed, as it flexibly compensates for these protrusions. This increases the versatility of the application and reduces the need for additional tools.

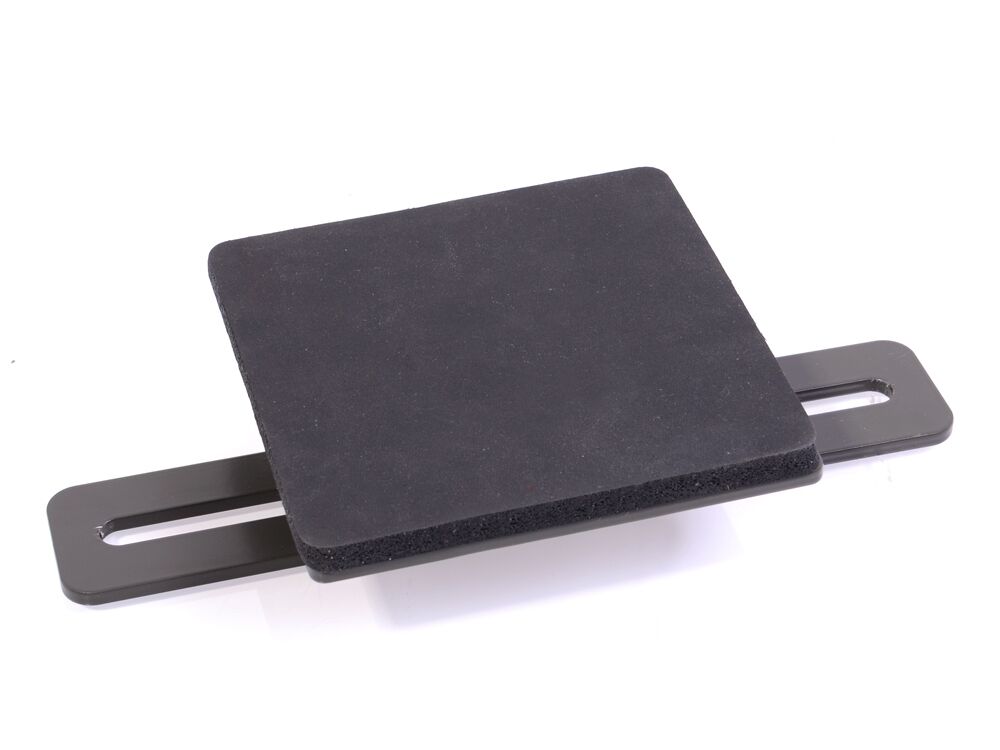

Use of Secabo exchangeable plates

In addition, exchangeable plates make it easy to process transfer areas and textile sizes of different sizes, which makes the workflow more flexible and increases productivity in the production process.

By using Secabo exchangeable plates, the pressing area can be massively reduced and limited to the transfer area. This protects particularly sensitive areas of the textile from unwanted pressure marks and ensures a significantly better end result.

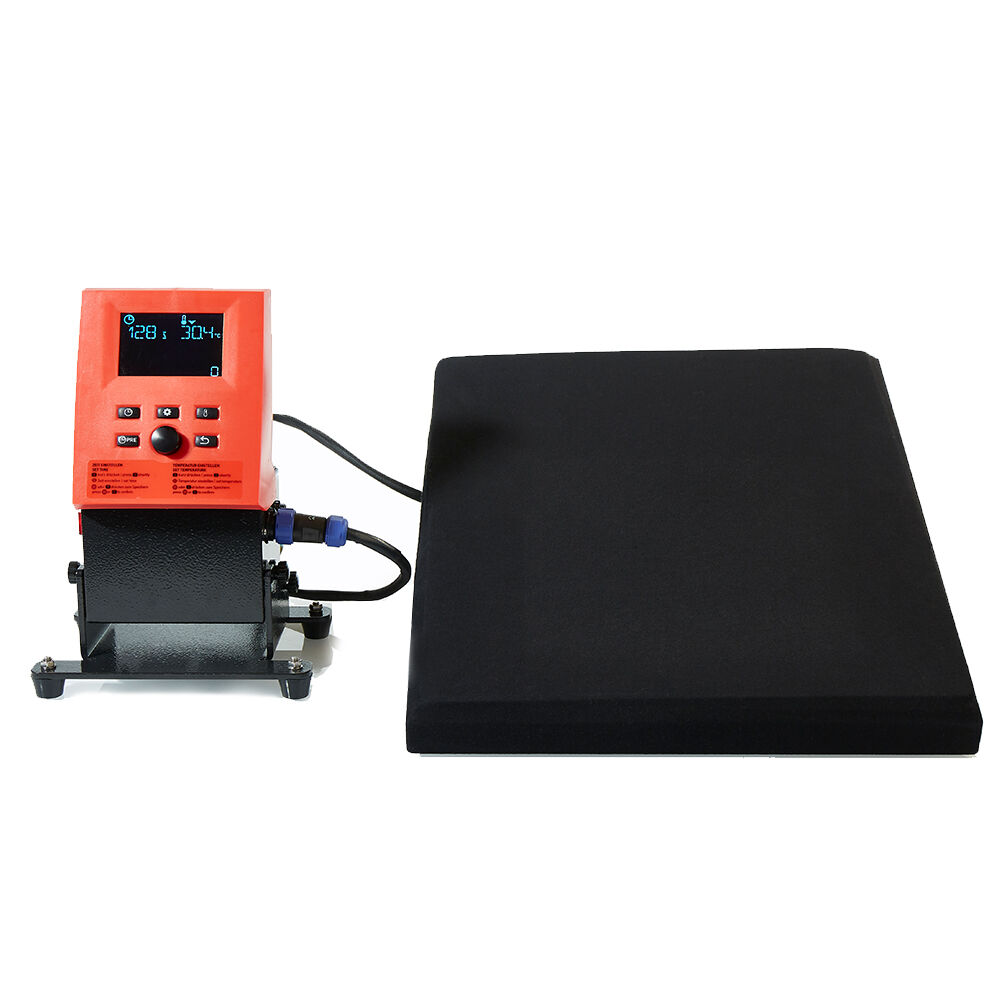

Using the TB7 heated base plate

The Secabo TB7 base plate enables even heating of the textile from below. This further reduces the temperature required on the upper heating plate, which additionally protects sensitive textiles and significantly reduces the formation of heat marks. In addition, the TB7 base plate accelerates the preheating phase of the textiles, thereby improving the overall production flow. The ability to control both plates separately offers optimum adaptation to different materials and transfer conditions, ensuring greater flexibility and efficiency in the production process.

Use of silicone mats

Secabo silicone mats serve as a soft cover on the textile, which dampens the pressing effect from above. This reduces the direct load on the textile fibres and effectively helps to prevent pressure marks. Silicone mats also ensure better adaptation to uneven or structured textile surfaces and protect sensitive transfers from direct heat. Their robust and durable nature enables frequent applications without significant wear and thus contributes to increasing efficiency in textile finishing in the long term.

Treatment after heat marks have already formed:

If heat marks have already formed, the following methods often help:

- Post-treatment with steam

- Brushing

- Washing

Conclusion

Heat marks are a common but avoidable problem when transferring textiles. Precise control of temperature, pressure and time, suitable tools and regular testing can significantly reduce the risk. Secabo offers solutions such as interchangeable heating plates or special membrane heating plates to minimise heat marks on sensitive textiles.