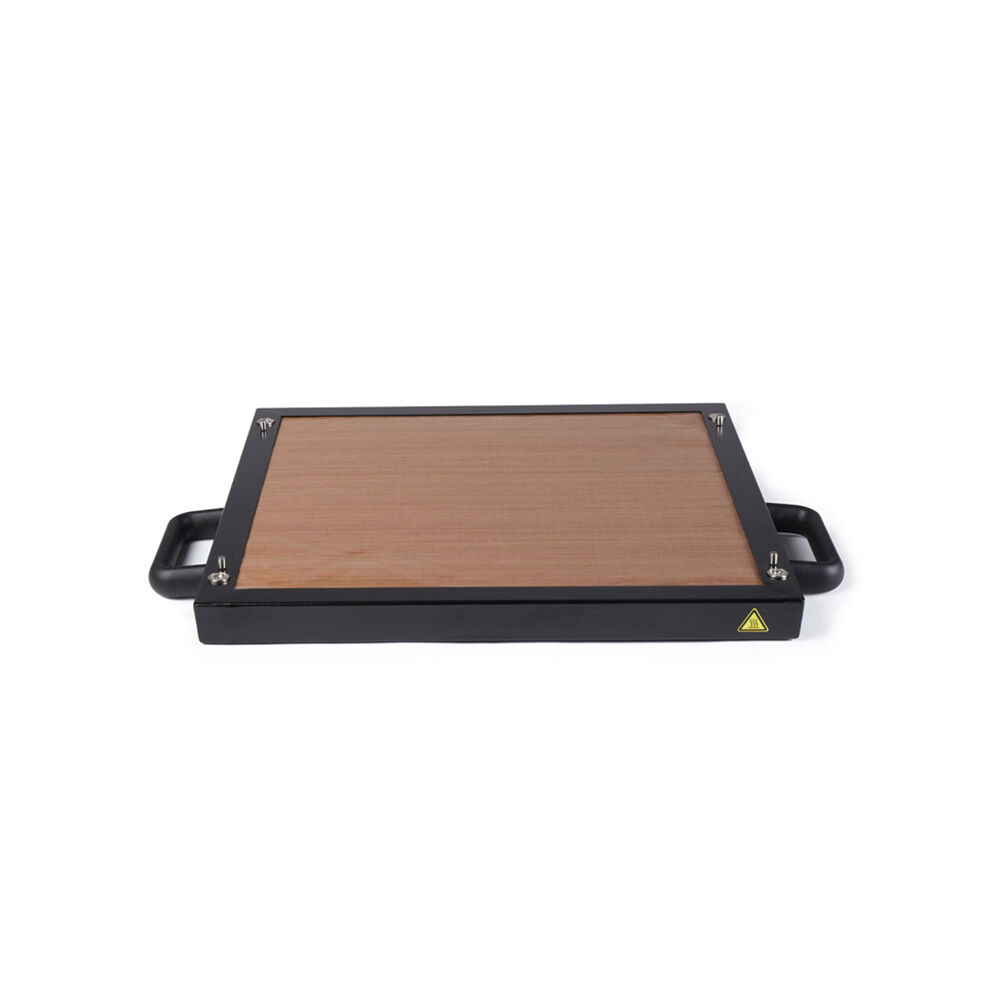

Secabo ES5 upgrade kit with cover

Energy efficiency redefined - Now also for your existing Heat Press.

Already own a TC5 LITE, TC5 SMART, TS5 Economy or TS 5 LITE? Optimise your machine with the Secabo ES5 Upgrade Kit. This innovative kit allows you to equip your existing Heat Press with the latest energy-saving and safety features. The supplied cover not only guarantees protection against possible burns, but also contributes significantly to energy savings. The simple upgrade process turns your existing Heat Press into a real energy saver - for more environmentally friendly and cost-efficient work.

Your existing Heat Press deserves the best. With the Secabo Energy Saver Upgrade Kits, you not only get an energy-saving solution, but also a safe and reliable workflow. Rely on innovation and quality - for a sustainable and efficient way of working.

Optimisation of your existing press:

- Compatible with the TC5 LITE, TC5 SMART, TS5 Economy and TS5 LITE models

- Energy-saving: Reduces the energy consumption of your machine and saves costs.

- Safety first: Included cover protects against possible burns.

- Environmentally friendly: Reduces the CO2 footprint of your Heat Press.

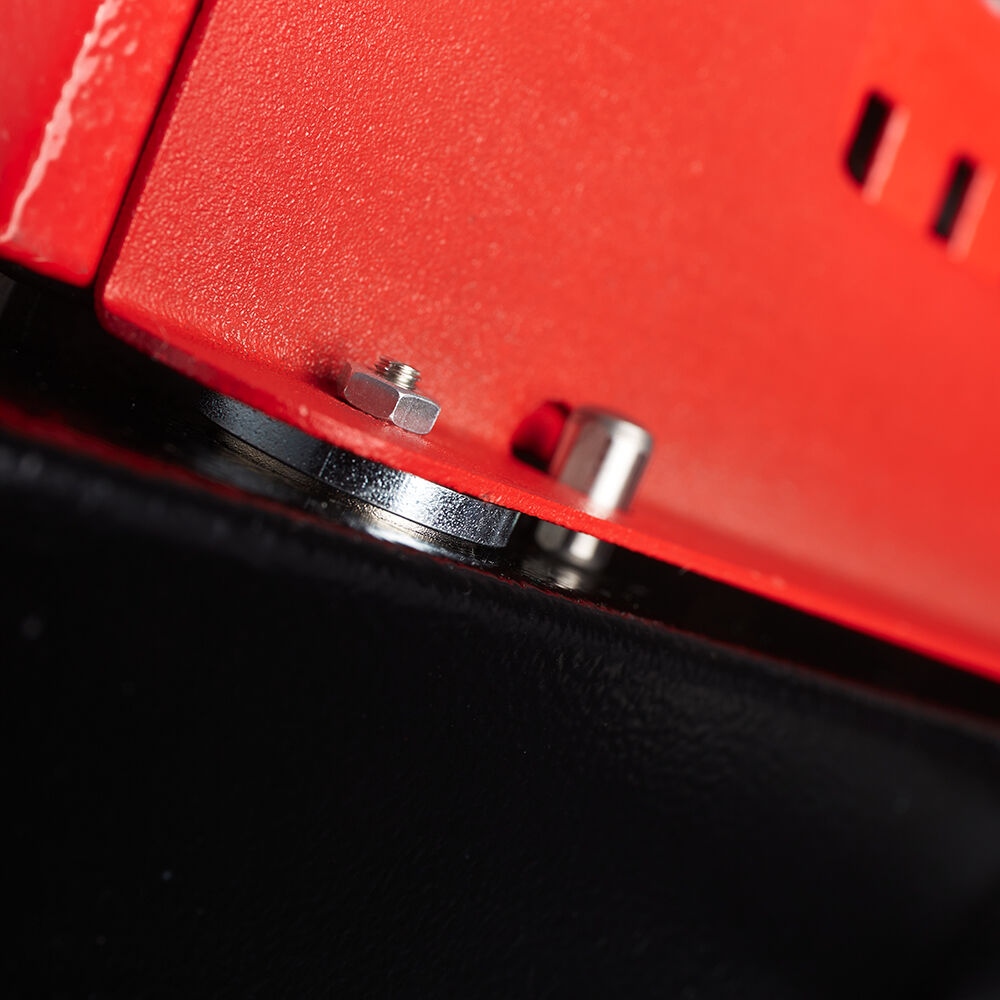

- Easy to install: Uncomplicated installation for a quick upgrade process.

| Technology: | Energy Saver |

|---|

| Gewicht mit Verpackung | 10,00 kg |

| Marke | Secabo |