Secabo TC1 Heat Press 15cm x 15cm

Product number:

109.001.10

GTIN/EAN:

4251486238579

Weight:

13,00 kg

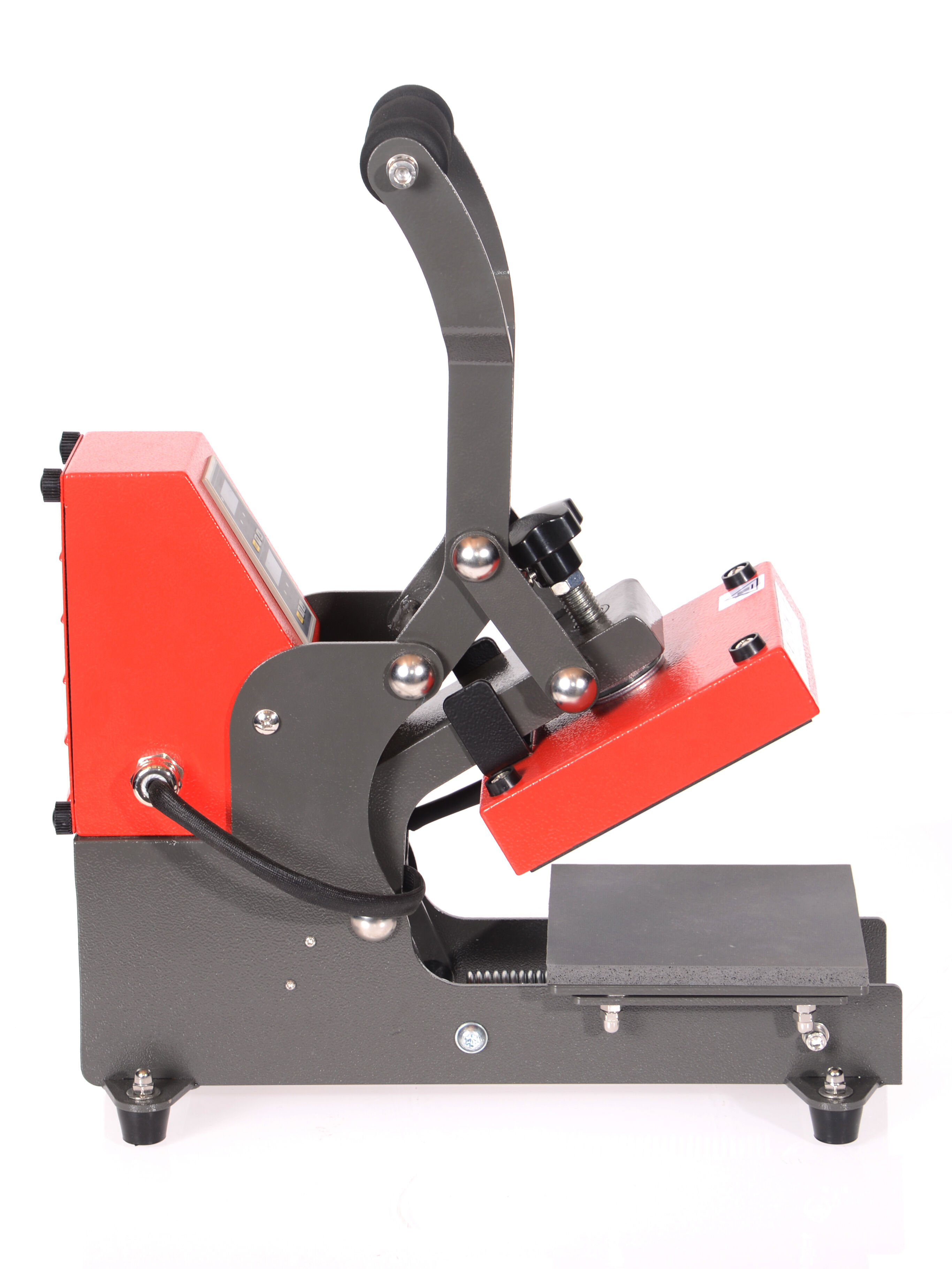

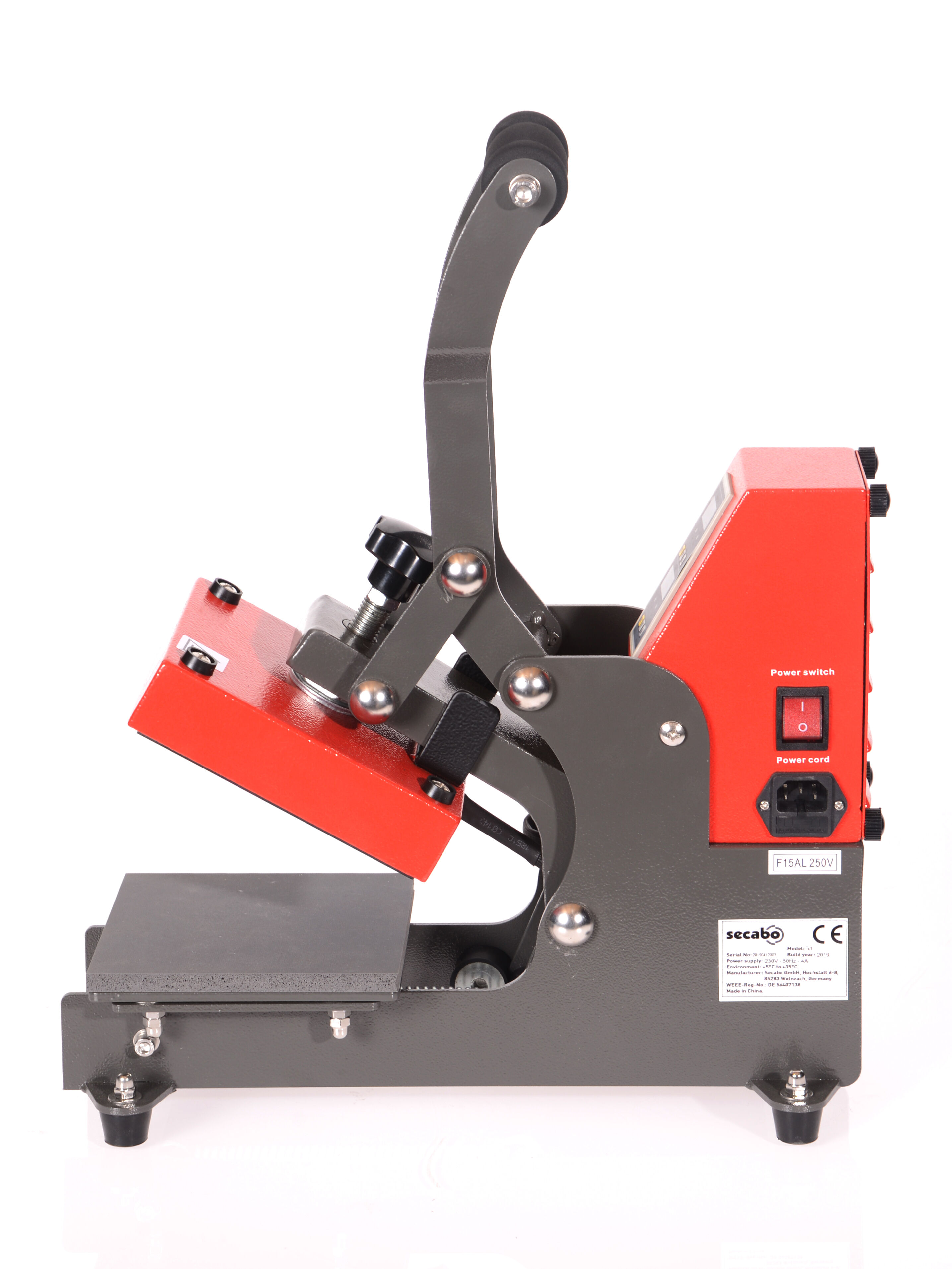

The TC1 Heat Press from Secabo has a working area of 15 x 15 cm. This makes it perfect for textile finishing, e.g. for emblems, patches, iron-on transfers, branding or product labelling. The TC1 is lightweight and very compact, making it ideal for mobile use at events. Our "little one" is also a favourable entry-level model.

The TC1 masters transfers on areas that are difficult to access, it presses specifically where it is desired and necessary. Above all, this prevents resublimation and dye migration.

The plate heats up quickly and has a low energy consumption. As you would expect from Secabo, the TC1 is easy to operate, even for beginners. The large opening angle makes it easy to prepare the transfer objects on the base plate. The time and temperature for the transfer can be precisely preselected on the digital controller. The contact pressure is set using the handwheel. Closing the pressing lever starts the pressing process.

| Application: | Textile |

|---|---|

| Features: | 15x15cm heating plate, Manual press |

| Series: | TC1 |

| Abmessungen | 16cm x 30cm x 42cm |

| Größe Arbeitsfläche | 15cm x 15cm |

| Lieferumfang | Transferpresse C13 Kaltgeräte-Anschlusskabel, Bedienungsanleitung |

| Druckeinstellung | Höhenverstellung der Heizplatte mittels Handrad |

| max. Anpressdruck | 200 g/cm² |

| max. Temperatur | 210 °C |

| max. Zeitvorwahl | 999 s |

| Klappwinkel | 0° - 40° |

| Schließsystem | manuelle Kniehebelpresse |

| Stromversorgung | 230V / 50Hz - 60Hz, 700 W |

| Umgebung | 5°C - +35°C / 30% - 70% Luftfeuchtigkeit |

| Gewicht ohne Verpackung | 12 kg |

| Gewicht mit Verpackung | 13,00 kg |

| Marke | Secabo |