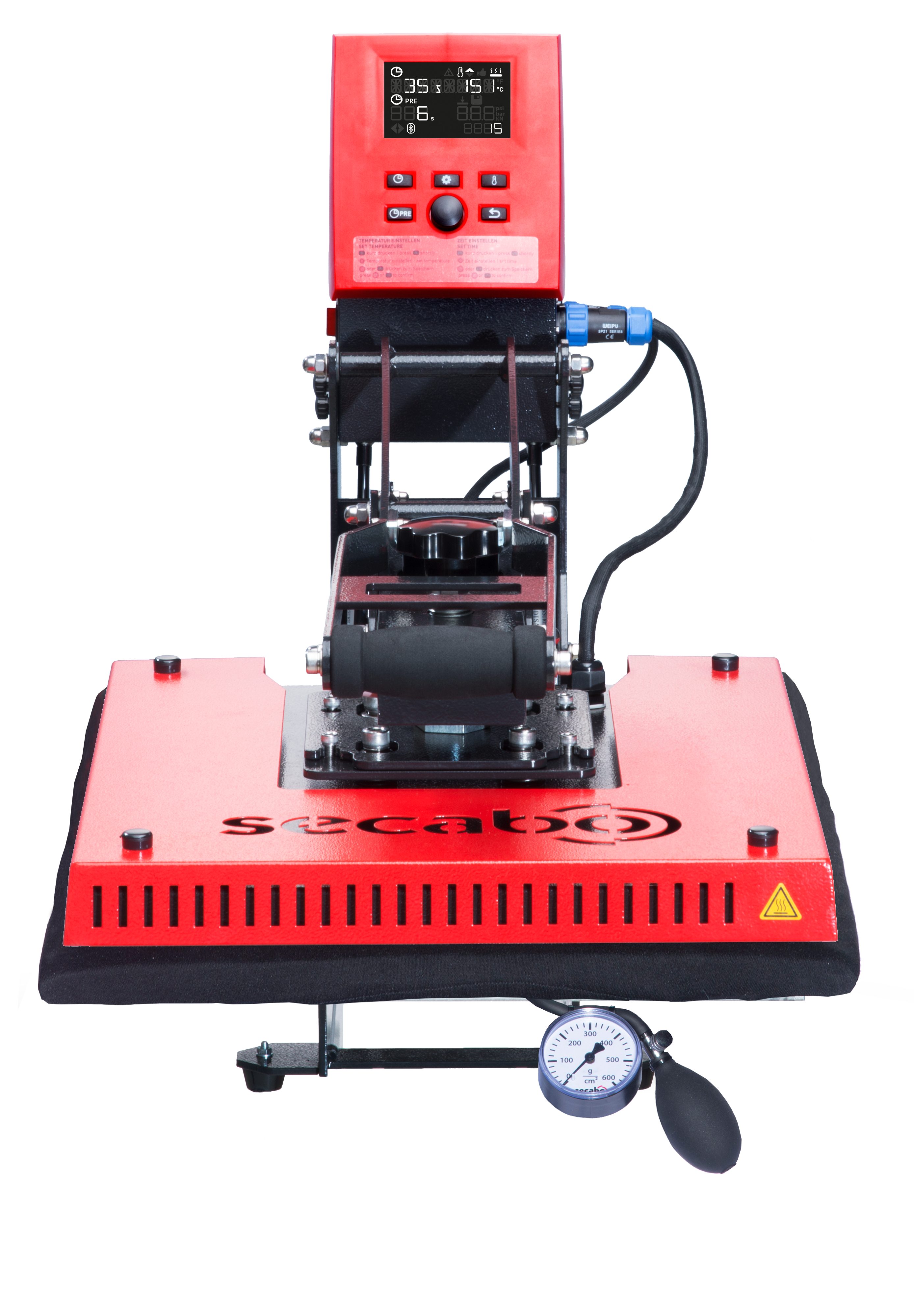

Secabo TC7 SMART MEMBRAN modular Heat Press 40cm x 50cm with Bluetooth

Product number:

109.007.16

GTIN/EAN:

4251486209258

Weight:

61,60 kg

This new development of the successful Secabo TC7 MEMBRAN automatic toggle press brings a world first to the market, opening up a wide range of new possibilities for users: For the first time, the controller of the TC7 SMART MEMBRAN is equipped with a Bluetooth interface which, with the free Secabo Smart Transfer app, allows the press to be controlled with simultaneous access to a comprehensive function database. For the user, this means: simply enter the fabric type and transfer material and the appropriate combinations for temperature, time and pressure can be called up. Additional functions such as the calculation of heat-up times and warning functions make the app a valuable aid for all common heat transfer processes. The new Secabo TC7 SMART MEMBRAN Heat Press offers a work surface of 40 cm x 50 cm, is easy to operate and robust during operation. The base plate of the Heat Press has a passive membrane. It opens up many new application possibilities - especially for transfer objects with large differences in height and unevenness. The membrane can be easily inflated using a small blower ball. This allows the user to determine the maximum levelling height of the membrane for a transfer. The contact pressure can be adjusted using a large handwheel at the top of the heating plate. When the Heat Press is closed, a pressure gauge reliably indicates the current contact pressure - in grams per square centimetre. During the pressing process, additional fine adjustment is possible via the blower ball and a release valve. With the TC7 SMART MEMBRAN, not only can the actual transfer pressure be read off, but it can also be repeatedly and reproducibly adjusted. The modular design allows quick and easy installation of exchangeable plates in various formats, quick-change system and slide extension. A conventional base plate is included in the scope of delivery alongside the membrane plate.

| Application: | Textile |

|---|---|

| Features: | 40x50cm heating plate |

| Series: | TC7 |

| Technology: | Bluetooth, Membrane plate, Smart |

| Abmessungen offen | 47cm x 93cm x 80cm |

| Abmessungen geschlossen | 47cm x 57cm x 80cm |

| Größe Arbeitsfläche | 40cm x 50cm |

| Größe Membran-Basisplatte | 47cm x 57cm |

| Lieferumfang | Mechanische Basis, Heizplatte, Basisplatte, Membran-Basisplatte, Befestigungs-Set, Controller Box, C13 Kaltgeräte-Anschlusskabel, Werkzeuge, Bedienungsanleitung |

| Druckeinstellung | Höhenverstellung der Heizplatte mittels Handrad, Feinjustierung mit Gebläseball und Ablassventil der Membran |

| max. Anpressdruck | 250 g/cm² |

| max. Temperatur | 225 °C |

| max. Zeitvorwahl | 999 s |

| max. Klappwinkel | 40 ° |

| Stromversorgung | Wechselspannung 230V / 50Hz - 60Hz, 2,0kW |

| Umgebung | +5°C - +35°C / 30% - 70% Luftfeuchtigkeit |

| Gewicht ohne Verpackung | 39 kg |

| Gewicht mit Verpackung | 61,60 kg |

| Marke | Secabo |