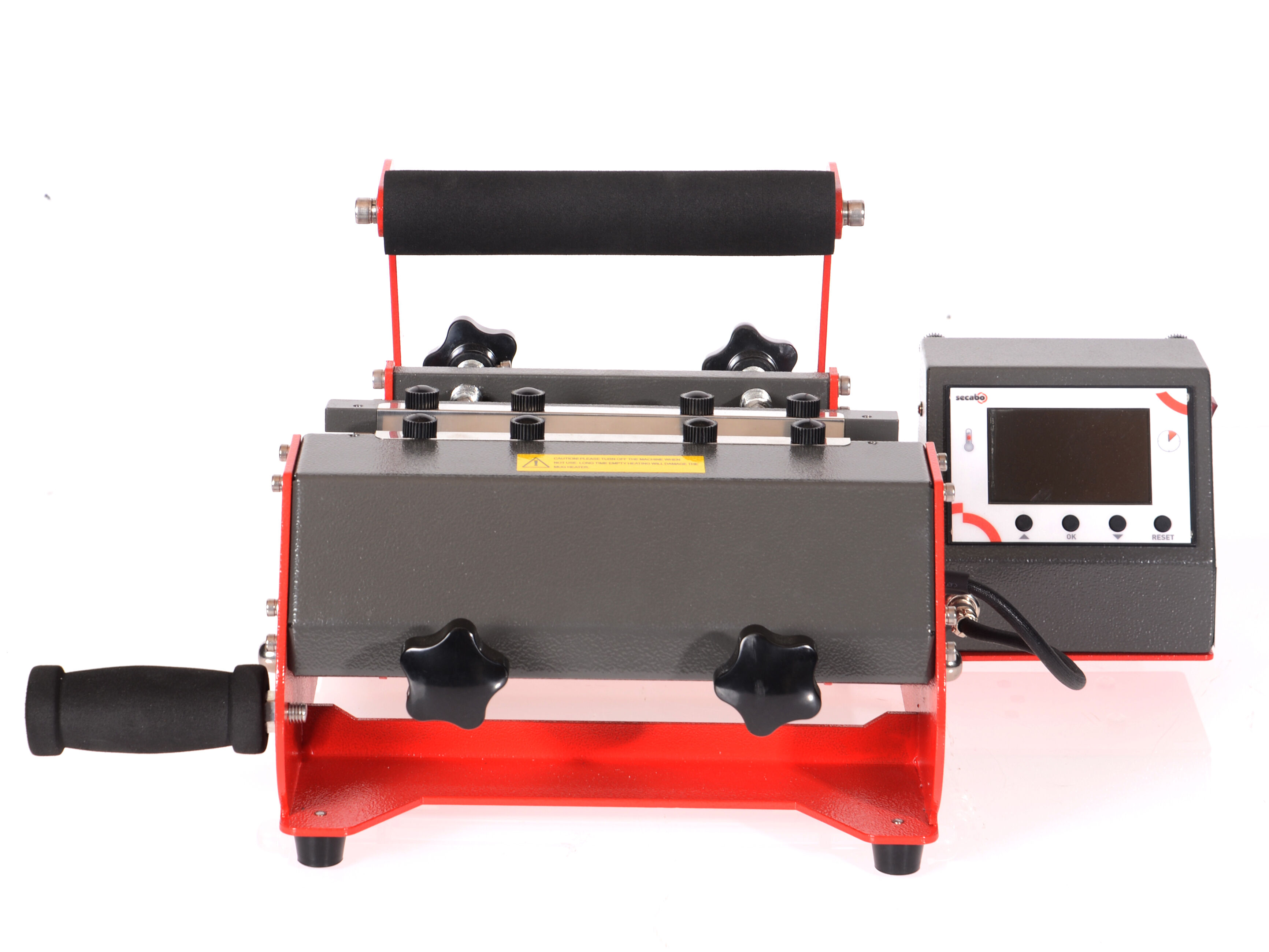

Secabo TM2 Mug Press

Product number:

109.016.10

GTIN/EAN:

4251486238562

Weight:

15,00 kg

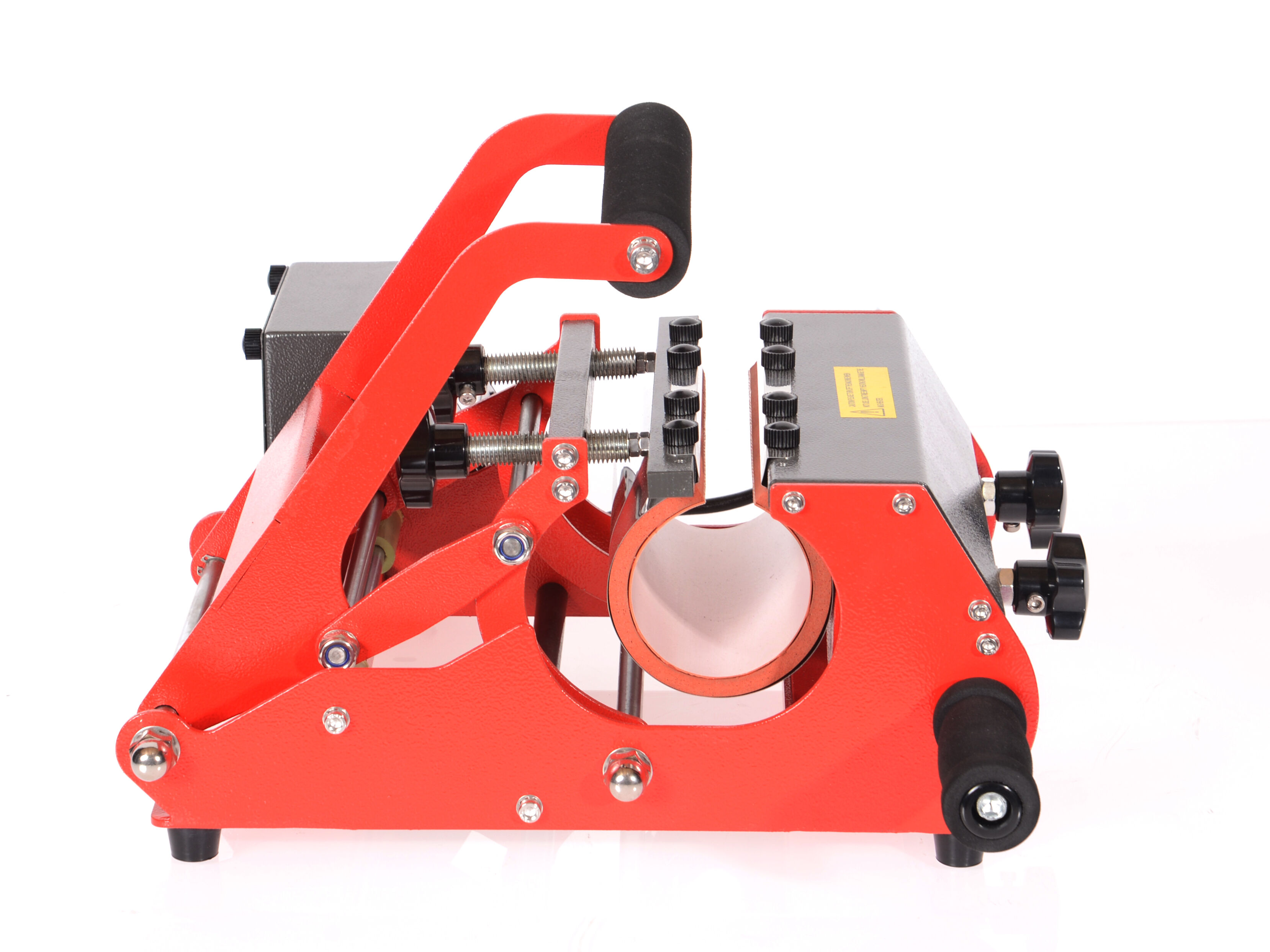

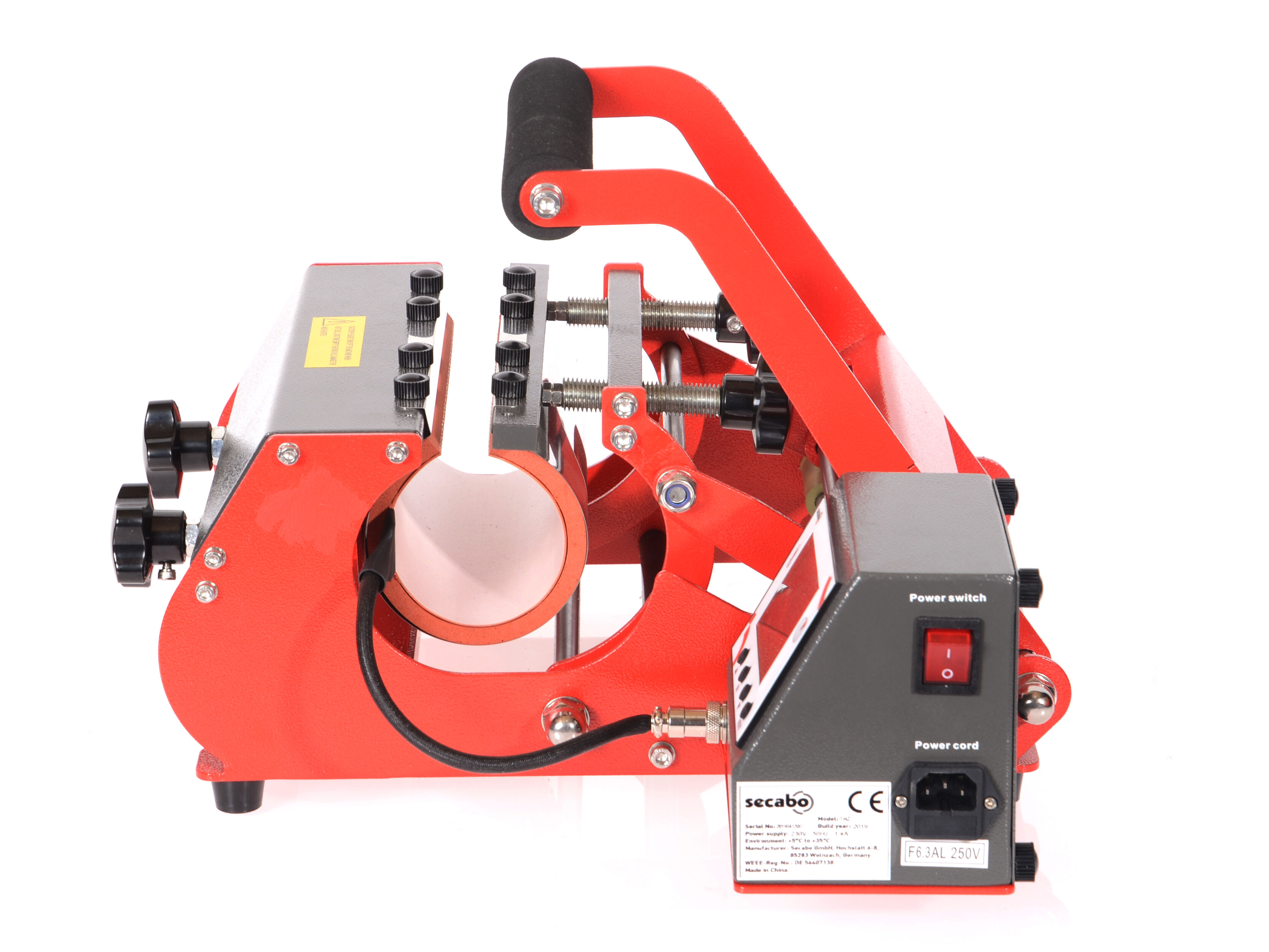

The TM2 Mug Press from Secabo has an extra-wide heating element that allows you to print 2 mugs at the same time - or a jug or large mug up to 21 cm high. Whether you are a beginner or a professional - with the TM2, sublimation transfers on ceramic cups and similar objects are particularly efficient. The digital controller controls the temperature and time precisely and reliably. The contact pressure can be easily adjusted using a handwheel. The device is supplied with a sleeve for 325 ml cups. Six additional heating elements in various sizes are optionally available, including for conical cups. Our recommendation: Only switch on the Heat Press for actual use, as this protects the heating element and saves energy.

| Application: | Cups |

|---|---|

| Features: | Manual press |

| Series: | TM2 |

| Abmessungen | 60,5cm x 42,8cm x 29,7cm |

| max. Tassenhöhe | 21 cm |

| max. Tassendurchmesser | 7,5cm bis 9,0cm cm |

| Optionen | Heizelement für Espresso Tassen, 4,5cm - 5,5cm; Heizelement für große konische Tassen 5,5/8,0cm - 6,5/9cm; Heizelement für Tassen 60mm - 75mm; Heizelement für konische Tassen 5,5/9,0cm - 6,5/10,5cm |

| Lieferumfang | Tassenpresse, Heizelement für 2 Tassen, 7,5 - 9,0cm, Stromkabel, Bedienungsanleitung |

| max. Temperatur | 225 °C |

| max. Zeitvorwahl | 999 s |

| Stromversorgung | 230V / 50Hz - 60Hz, 300W |

| Umgebung | +5°C - +35°C / 30% - 70% Luftfeuchtigkeit |

| Gewicht ohne Verpackung | 10 kg |

| Gewicht mit Verpackung | 15,00 kg |

| Marke | Secabo |