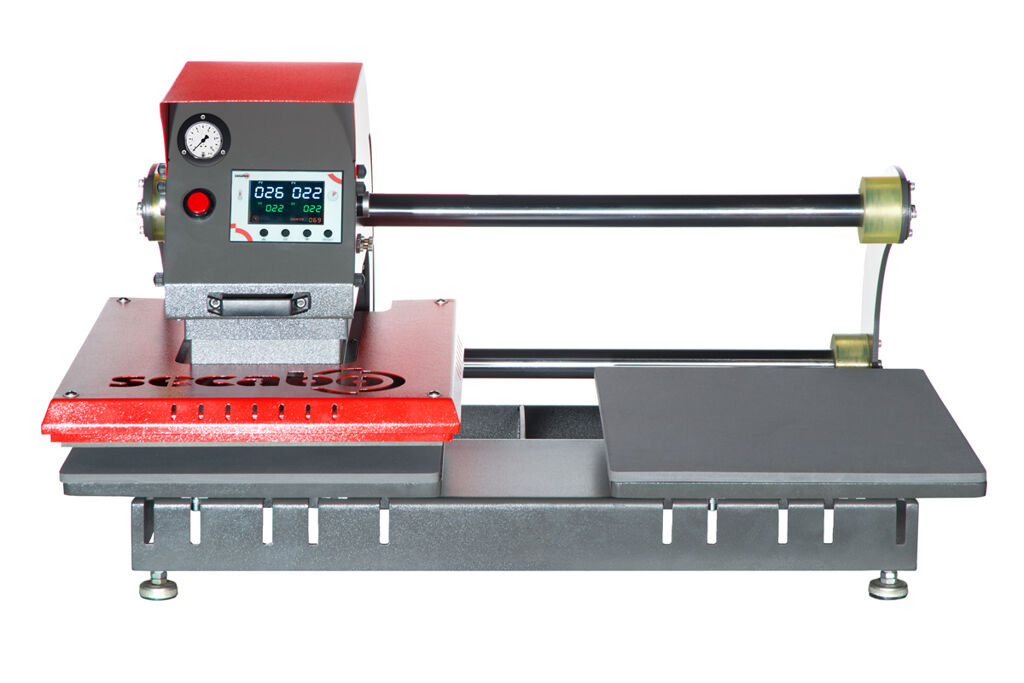

Secabo TPD7 Pneumatic double platen press

The new TPD7 Heat Press from Secabo is the perfect solution for large-format and extensive transfers with all common transfer processes in large print runs. This double-plate Heat Press works with compressed air, which ensures easy working with consistent and reproducible results. With a size of 40cm x 50cm each, the two work plates offer a particularly generous working area for conveniently aligning the transfer objects. Thanks to the vertical arrangement of the base plates, in contrast to the previous model, the exact positioning of the objects to be transferred is even easier. The convenient work surface on the exposed base plate increases the quality and precision of the transfers. The horizontally movable heating plate head can be easily aligned over the respective work plate, and the vertical contact pressure enables error-free transfer of a wide range of materials without offset effects.

Special features of the TPD7 Heat Press:

- High heat output and heat capacity of the heating plate, good heat distribution

- Easily adjustable and reproducible pneumatic pressure

- Extensive range of accessories available

- Safe working thanks to 2-hand operation

- Suitable for handling high order volumes

- Perfect press for DTF transfers and the DTF pressing process

Note for exchangeable plates and adapters:

- Smaller interchangeable plates are available separately (8x12 cm, 12x38cm, 15x15cm, 20x30cm) and can only be mounted in combination with the Secabo interchangeable plate quick changer for TPD7 (art. no. 109.505.16)!

- For the optional Secabo base plate 38cm x 38cm (art. no. 109.505.40), the adapter for base plate and S.-W. Secabo TC5, TS7 (art. no. 109.505.30) is required in addition to the above-mentioned quick changer!

- If you also want to connect the original plate of the TPD7 to the quick coupler, you will need the adapter for base plate and S.-W. Secabo TC7, TPD7 (art. no. 109.505.31).

| Application: | Chromaluxe, Textile, White toner |

|---|---|

| Features: | 2 base plates, 40x50cm heating plate, auto open press |

| Series: | TPD7 |

| Abmessungen | 100cm x 58cm x 75cm |

| Größe Arbeitsfläche | 2 x 40cm x 50cm |

| Lieferumfang | Transferpresse, Stromkabel, Anschluss-Set für Kompressor, deutschsprachige Bedienungsanleitung |

| Druckeinstellung | Einstellung des Pneumatikdrucks |

| Empfohlene Druckluft | Druckluft-Qualitätsklassen nach ISO 8573-1:2010 (1:4:2) |

| max. Anpressdruck | 350 g/cm² |

| max. Temperatur | 225 °C |

| max. Zeitvorwahl | 999 s |

| Stromversorgung | Wechselspannung 230V / 50Hz - 60Hz, 1,8kW |

| Umgebung | +5°C - +35°C/ 30% - 70% Luftfeuchtigkeit |

| Gewicht ohne Verpackung | 88 kg |

| Gewicht mit Verpackung | 170,00 kg |

| Marke | Secabo |