Heat Presses for DTF Technology: Which is the right choice?

Heat Presses are an indispensable tool when it comes to transferring customised designs onto a wide variety of materials. With the growing popularity of DTF (Direct to Film) technology, you have even more options for realising creative and high-quality designs. But which Heat Press is best suited for DTF applications? In this article, we give you an overview of the different types of Heat Presses and explain why pneumatic presses are particularly advantageous for DTF.

What is DTF technology?

DTF technology makes it possible to print designs directly onto a special film, which is then transferred to textiles using a Heat Press. This opens up new possibilities for high-resolution and colourful prints, which are particularly suitable for complex patterns and colour gradients. Choosing the right Heat Press is crucial to achieve optimal printing results.

ClamPresses are still a popular tool in textile printing due to their compact design and ease of use. They work in a similar way to a waffle iron: The material to be printed is placed on the base plate and the heating plate is folded over it using a lever. This type of press is particularly suitable for flat materials such as T-shirts and is ideal for beginners.

For DTF applications: Clam Presses can also be used for DTF, but they are less precise due to the manual contact pressure. For simple and small DTF projects, they are still a good and cost-effective choice.

Pneumatic Heat Presses: The perfect solution for professional DTF production

Professional finishers who want to produce a high number of DTF transfers in a short time with consistently high quality are better advised to use a pneumatic Heat Press. The contact pressure is generated by compressed air, which ensures an even distribution of pressure. This is particularly important with DTF, as the even transfer of the film to the textile is crucial for the end result. Advantages of pneumatic Heat Presses for DTF: Constant pressure: Regardless of the thickness of the material, the pressure is always applied evenly, which ensures clear and detailed results, especially with DTF. High repeat accuracy: It is particularly important for series production of DTF transfers that every print is identical. This is guaranteed by the precise pressure control of a pneumatic press. Low effort: The pressing process can be carried out conveniently using two-handed operation, which makes work easier and increases efficiency.

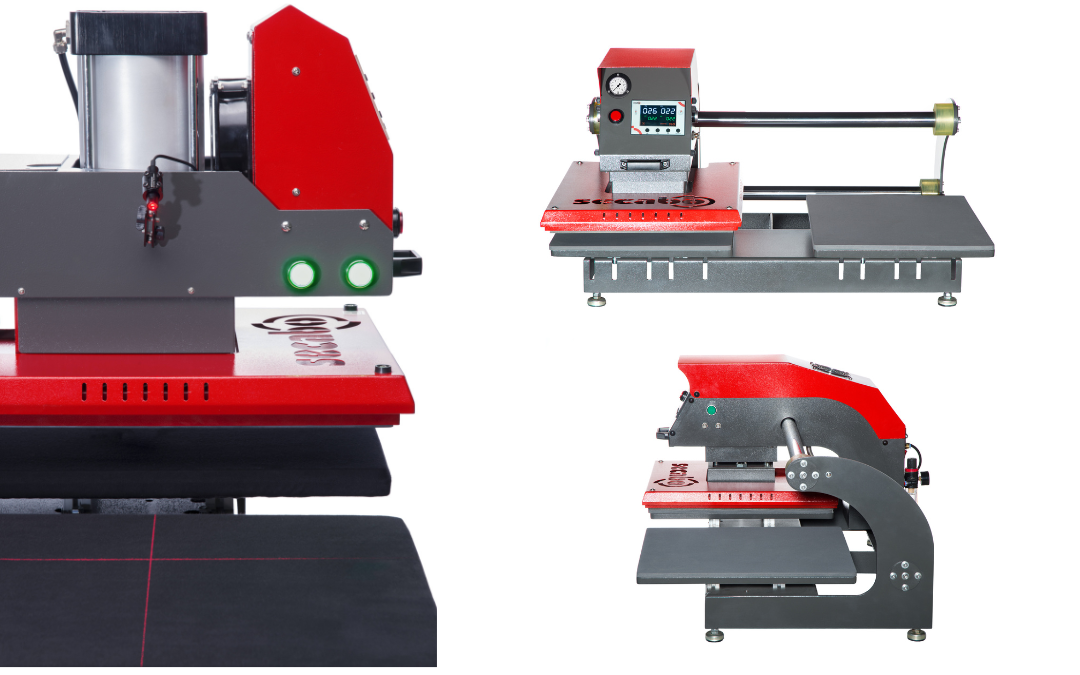

DTF-optimised Heat Presses at a glance Secabo TPD7: The practical double plate system

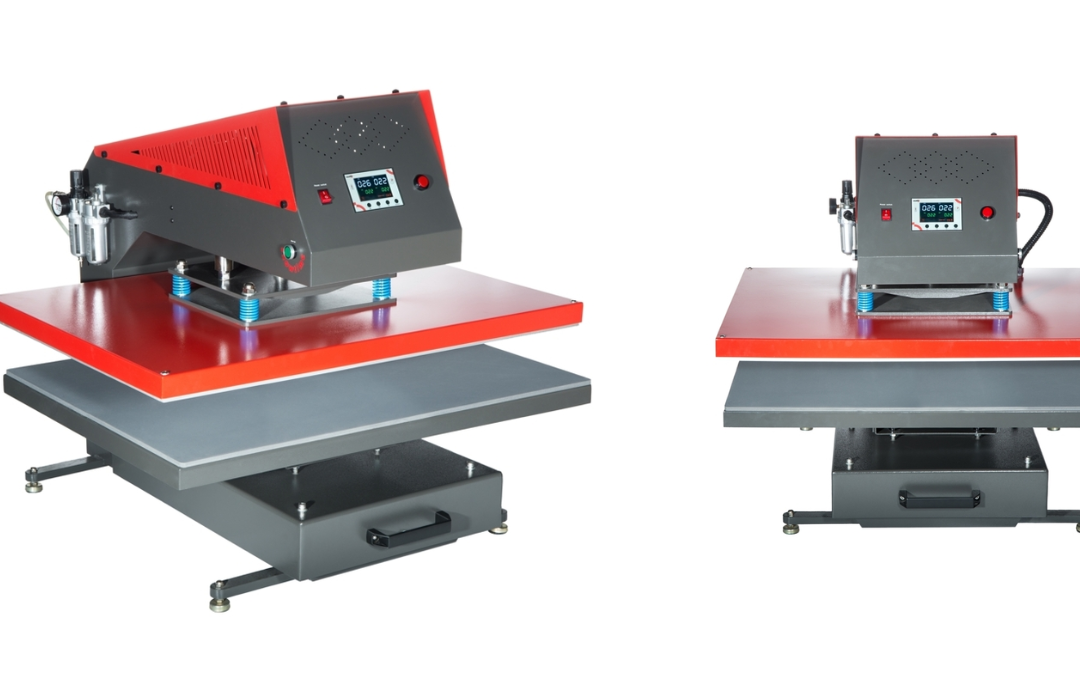

Secabo TP10: The workhorse for large DTF productions

For even larger productions, the Secabo TP10 with a working area of 80×100 cm offers sufficient space for large-format DTF transfers. This press is ideal if you want to print large-format carrier media such as flags or bed linen. With the height-adjustable and extendable base plate, you can also process different material thicknesses with ease.

Conclusion: Which press is the best choice for DTF? Choosing the right Heat Press depends on your specific area of application and the materials to be printed. While Clam Presses may be sufficient for simple DTF applications, pneumatic presses offer the necessary precision and efficiency for professional and large-format DTF projects.