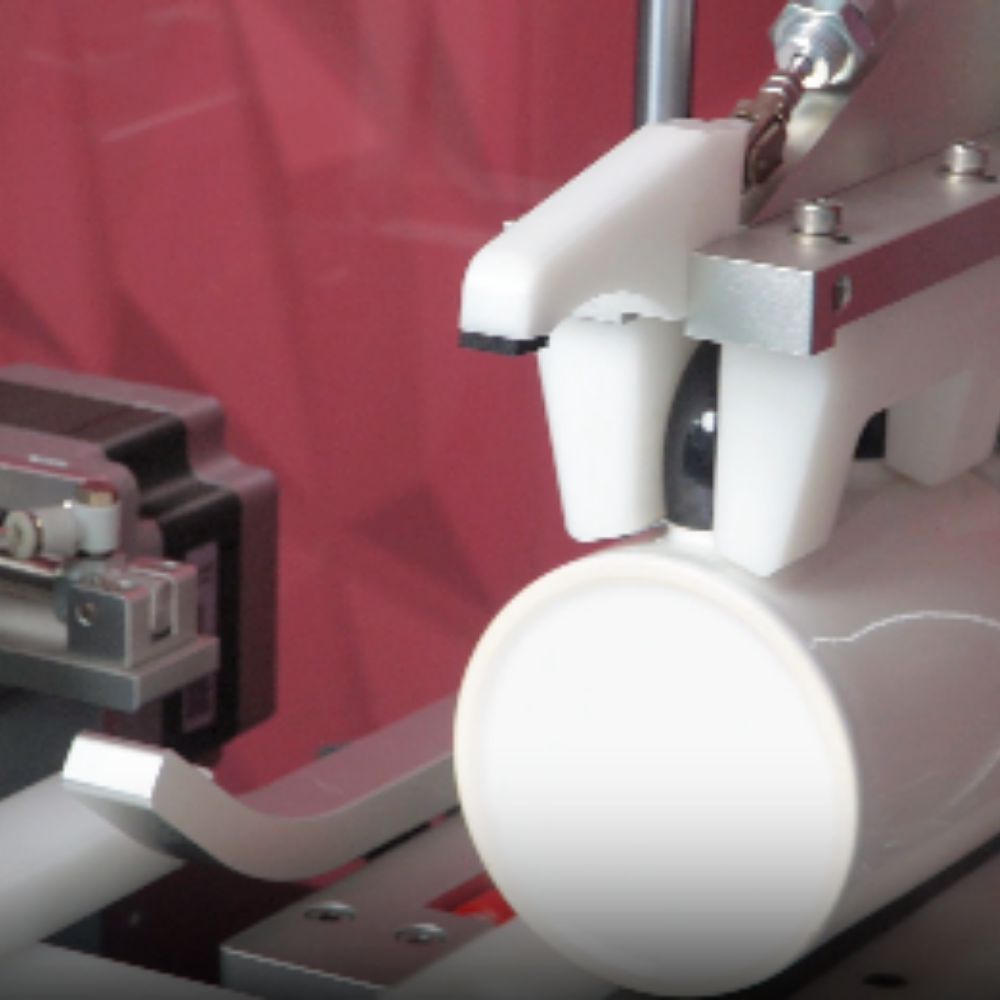

Secabo MugWrap Station

Automated mug production at the highest level

The Secabo MugWrap Station revolutionises the mug finishing process by applying transfers fully automatically using thermal tape. This high-end solution has been specially developed for companies that value speed, precision and consistently high quality.

With an output of up to 360 cups per hour, the MugWrap Station offers maximum efficiency with minimum labour requirements. The automated wrapping process ensures perfect positioning of the transfers - error-free, fast and reliable.

In combination with the Secabo MultiCut Pro for pre-cut sublimation or DTF transfers, a seamless workflow is created for professional cup production.

Advantages of the Secabo MugWrap Station

Automatic application of transfers to mugs with thermal tape

High production speed: up to 360 cups per hour

Perfect positioning - reduces errors and rework

Compatible with 11oz and 15oz cups - ideal for standard sizes

Consistent, high quality results with every batch

Can be optimally integrated into existing production lines

Increased efficiency through automation

The MugWrap Station takes over the entire wrapping process, which is otherwise carried out manually in a time-consuming process. This significantly speeds up and standardises the preparation for sublimation or DTF transfer - perfect for series production and print-on-demand jobs.

Typical areas of application

Sublimation mug production

DTF transfer to cups

Personalised mugs for promotional items and gifts

Print-on-demand services with high throughput

Conclusion

The Secabo MugWrap Station is the ideal solution for anyone who wants to make their mug production more efficient and error-free. With its high speed, automatic precision and easy integration into existing workflows, it is a must-have for professional sublimation companies and suppliers of personalised mugs.0 of 0 reviews

Average rating of 0 out of 5 stars