Secabo machines - Professional technology for textile finishing, advertising technology and creative productions

Secabo machines have stood for high quality, precision and reliability in textile finishing and advertising technology for years. Heat Presses, cutting plotters or Badge Making Machines - Secabo provides professionals and beginners with powerful tools to create customised products efficiently and to a high standard.

Our devices are used wherever precise processing, flexible applications and durable technology are required - e.g. in T-shirt printing, film labelling, advertising material production or sublimation printing.

Filter products

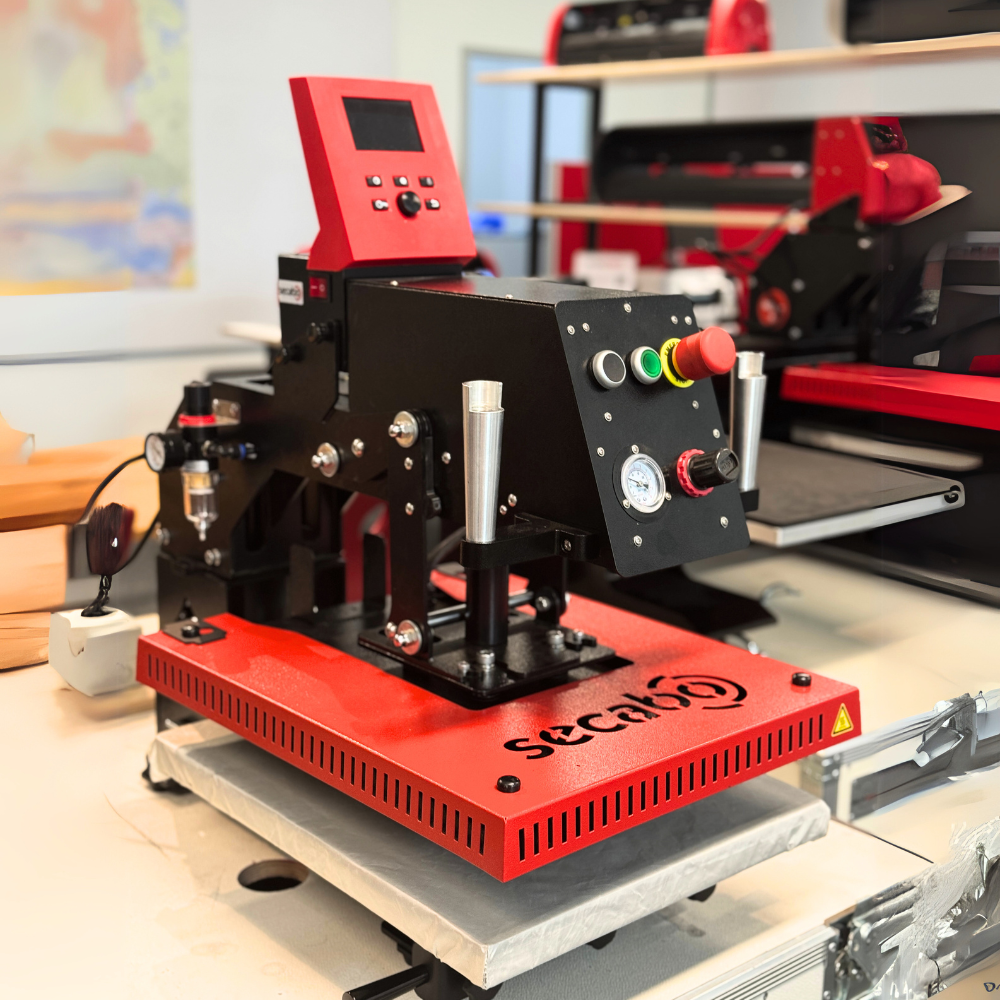

Secabo TPS7 SMART

The smart pneumatic transfer press for maximum efficiencyThe Secabo TPS7 Smart is the perfect solution for anyone who values efficiency, precision and flexibility. This pneumatic Heat Press impresses with its modular design and intelligent control via app, which makes the work process much easier.Whether DTF transfers, flex or flock foils or sublimation - with the TPS7 Smart, you can process a wide variety of materials quickly, reliably and with consistently high quality. The pneumatic contact pressure ensures reproducible results without manual effort, ideal for series production and professional textile finishing.Modularity meets intelligent controlThe TPS7 Smart is part of the proven Secabo modular system. Components such as heating plates, base plates or the controller are interchangeable and can be supplemented with accessories such as the thermobase or the quick-change system. This allows the press to be flexibly adapted to your production requirements.It is conveniently controlled via the Secabo Smart app via Bluetooth. This allows you to digitally control temperature, time and pressure and efficiently manage recurring jobs.Advantages of the Secabo TPS7 SmartPneumatic press head for even contact pressure without effortSmart app control for precise control and digital workflowsOptional drawer for convenient and safe workingModular design - compatible with the entire Secabo accessory systemTwo-hand safety operation for professional useRobust construction with encapsulated guides for minimal maintenanceTypical areas of applicationDTF transfer production of medium quantitiesFlex and flock finishing in advertising technologySublimation printing on textiles, bags and other materialsPersonalised series production in textile printingConclusionThe Secabo TPS7 Smart offers you a professional solution for flexible production requirements. With its intelligent control system, pneumatic system and modular expandability, it is the ideal press for growing businesses that prioritise efficiency and quality.

Secabo MugWrap Station

Automated mug production at the highest levelThe Secabo MugWrap Station revolutionises the mug finishing process by applying transfers fully automatically using thermal tape. This high-end solution has been specially developed for companies that value speed, precision and consistently high quality.With an output of up to 360 cups per hour, the MugWrap Station offers maximum efficiency with minimum labour requirements. The automated wrapping process ensures perfect positioning of the transfers - error-free, fast and reliable.In combination with the Secabo MultiCut Pro for pre-cut sublimation or DTF transfers, a seamless workflow is created for professional cup production.Advantages of the Secabo MugWrap StationAutomatic application of transfers to mugs with thermal tapeHigh production speed: up to 360 cups per hourPerfect positioning - reduces errors and reworkCompatible with 11oz and 15oz cups - ideal for standard sizesConsistent, high quality results with every batchCan be optimally integrated into existing production linesIncreased efficiency through automationThe MugWrap Station takes over the entire wrapping process, which is otherwise carried out manually in a time-consuming process. This significantly speeds up and standardises the preparation for sublimation or DTF transfer - perfect for series production and print-on-demand jobs.Typical areas of applicationSublimation mug productionDTF transfer to cupsPersonalised mugs for promotional items and giftsPrint-on-demand services with high throughputConclusionThe Secabo MugWrap Station is the ideal solution for anyone who wants to make their mug production more efficient and error-free. With its high speed, automatic precision and easy integration into existing workflows, it is a must-have for professional sublimation companies and suppliers of personalised mugs.

Secabo MugPro

Fully automated mug production for the highest demandsThe Secabo MugPro is the ultimate solution for the automated mass production of sublimation mugs. With its 15-station system and a fully robotised workflow, this high-end Mug Press is aimed at companies that demand maximum efficiency and quality in print-on-demand (POD) or series production.The MugPro takes care of the entire process: from automatic loading and unloading of the cups to precise pressing and the integrated cooling line at the end of the production line. With an output of up to 250 cups per hour, the MugPro replaces several manual workstations and significantly reduces production costs.Advantages of the Secabo MugPro15 fully automatic heating stations for continuous productionConveyor belt system for automatic loading and unloadingRapid cooling at the end of the production line for shorter cycle times360° heat distribution for perfect, even transfer resultsIndividually adjustable heating stations - process different materials simultaneouslyExtremely low error rate (<0.1%) - maximum production reliabilityIdeal for 11oz standard cupsMaximum efficiency with minimum labour inputThe MugPro enables fully automatic cup production with just one operator. In combination with other automation solutions - such as the MugWrap Station and the MultiCut Pro - a complete production line can be set up that covers the entire process from cutting to the finished product.Typical areas of applicationPrint-on-demand (POD) providersSublimation printers with high cup volumesSeries production of individualised promotional cupsOEM production and large orders for branded productsConclusionThe Secabo MugPro is the perfect choice for professional cup production with high throughput. Fully automatic, efficient and reliable - this machine sets new standards in the sublimation industry and offers a future-proof solution for growing production requirements.

Secabo MultiTrim Pro

The professional roll trimmer with intelligent film trackingThe Secabo MultiTrim Pro is the efficient solution for the precise trimming of DTF transfers, mug wrappers and other transfer materials in roll form. This automatic roll trimmer impresses with its speed, reliability and an intelligent film tracking system that continuously monitors the position of the film during operation.The special feature: After adjusting the blades once at the start, the film tracking system ensures that the trimmer knows exactly where to cutat all times - even if there are minimal movements or changes in tension in the film. This ensures consistent cutting quality over the entire length of the web.Advantages of the Secabo MultiTrim ProIntelligent film tracking for precise cutting over long websKnives are adjusted at the start - the process then runs stably and reliablyIdeal for DTF standard transfers and mug wrapper productionFaster than a DTF cutter with consistent formatsCost-efficient alternative for entry into professional finishingCompatible with marking systems such as Fotoba or SagaEfficient cutting for standardised productionsThe MultiTrim Pro is the perfect choice for companies that want to trim large quantities of transfers in fixed formats. Compared to complex cutting systems such as the DTF Cutter, the trimmer scores with its ease of use, speed and excellent price-performance ratio.Typical areas of applicationSeries cutting of DTF transfersProduction of mug wrappers for sublimation mugsTrimming of roll goods in the field of advertising technology and textile finishingSupplement or alternative to fully-fledged cutters for standard applicationsConclusionThe Secabo MultiTrim Pro offers a reliable and economical solution for the professional trimming of transfer materials. This trimmer is an indispensable tool for increasing efficiency and precision, especially for companies with standardised productions.

Secabo BladeX2

High-precision cutting plotter for maximum efficiencyThe Secabo BladeX2 is the perfect solution for professional cutting applications in the fields of DTF transfers, UV stickers, label production and classic advertising technology. Equipped with an innovative dual-head cutting system, this plotter enables different types of cutting to be carried out simultaneously - ideal for production companies with high throughput and variable requirements.The combination of state-of-the-art servo technology, automatic material feed (optional) and intelligent register mark recognition ensures maximum precision, even with complex designs and long production runs.Advantages of the Secabo BladeX2Dual-head cutting system for parallel cutting processesSuitable for kiss-cut (half cut) and full cut in one work processServo motor for particularly smooth running and maximum cutting accuracyCCD camera for automatic recognition of register marks and cutting pathsAutomatic material feed (optional) for efficient series productionWide range of connection options: USB, network, WiFiFully integrated into the Secabo software universe with DrawCut PRO and plugins for CorelDraw & Adobe IllustratorFuture-proof thanks to regular firmware updatesEfficiency and precision for demanding productionsThe BladeX2 was developed for companies that place the highest demands on speed, accuracy and workflow integration. The plotter demonstrates its strengthsparticularly in label production, UV stickers or in the DTF area and reduces manual reworking to a minimum.Typical areas of applicationDTF transfer cuttingProduction of stickers and labelsUV sticker series productionContour cutting for advertising technology and labellingPrint & cut applications with automatic register mark recognitionConclusionThe Secabo BladeX2 is the ideal choice for anyone who wants to take their cutting processes to a new level. With its innovative dual-head system, intelligent software integration and maximum precision, it offers a future-proof solution for a wide range of applications in advertising technology and production environments.

Secabo T60 III

Future-proof cutting solution for precise print & cut workflowsThe Secabo T60 III is the next generation of professional cutting plotters for signmaking, textile finishing and DTF applications. With its new Qaptur register mark recognition, 40% higher speed compared to the previous model and comprehensive software integration, the T60 III sets new standards in terms of efficiency and precision.Thanks to the standard DrawCut PRO software and direct connection to CorelDraw and Adobe Illustrator, the T60 III is perfectly integrated into modern production workflows. The integrated QR code function enables automatic job recognition - ideal for changing jobs and series production.Regular firmware updates ensure that the plotter constantly receives new functions and thus remains future-proof in the long term.Advantages of the Secabo T60 IIIQaptur system: state-of-the-art register mark recognition for precise contour cuts40% faster than the previous model - more output in less timeAutomatic job recognition through QR code functionDrawCut PRO included - professional cutting software at no extra costDirect integration into CorelDraw & Adobe Illustrator via plug-inCompatible with leading software solutions such as Digital Factory, Caldera, Colorgate, Flexi, Ergosoft, SignCut, Productivity ProRobust design for continuous useFuture-proof thanks to continuous firmware updatesTypical areas of applicationDTF transfers and print & cut applicationsFlex and flock cutting in textile finishingProduction of stickers, labels and advertising letteringSeries production with changing layoutsTechnical highlightsImproved camera technology for more precise detectionFaster work thanks to optimised mechanics and control QR code systemfor automating production processesFull integration into common graphics and RIP softwareConclusionThe Secabo T60 III is the ideal solution for companies looking for a precise, fast and future-proof cutting solution. With state-of-the-art recognition technology, intelligent software integration and high processing speed, this plotter is perfect for anyone who wants to organise their production processes efficiently.

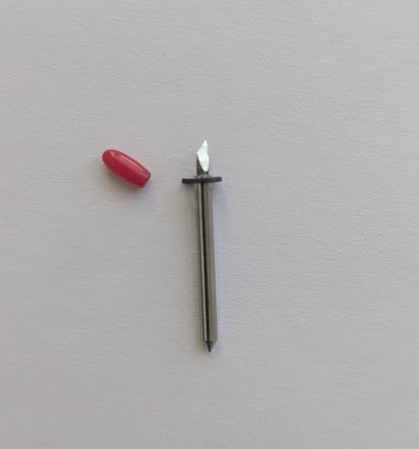

Drag knife 45° with clip for Secabo DTF MultiCut Pro

Drag knife for small fonts. Cutting angle 45°, wedge angle 45°, offset 0.25 mm.

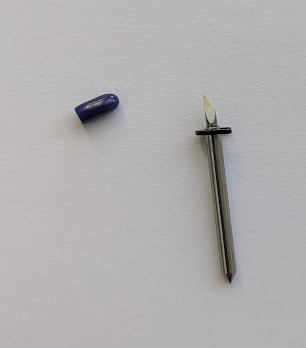

Drag knife 60° with clip for Secabo DTF MultiCut Pro

Drag knife 60° with clip for Secabo DTF MultiCut Pro

Secabo quick-change plate changer for TS7 swingaway (not for TS7 LITE/SMART)

With the quick-change system, up to three interchangeable plates can be mounted next to each other - depending on the Heat Press model - and exchanged in just a few seconds. Interchangeable plates must be ordered separately. The scope of delivery includes an adapter for mounting the original base plate on the quick coupler. The special beam technology of the adapter allows textiles to be conveniently pulled over the base plate. (The interchangeable plates in the product image are not included in the scope of delivery).

Set of 4 Secabo removable discs

4 plates for the price of 3 - Set consisting of four interchangeable plates for Secabo Heat Presses for the price of three. The set includes the plates in the sizes 12cm x 38cm, 15cm x 15cm, 20cm x 30 cm and 8cm x 12cm.Suitable for the current Secabo models, e.g. TC5 LITE/SMART, TC7 LITE/SMART, TS5 LITE, TS7 LITE, TPS7 SMART SMART, TD7 LITE, TPD7, TPD7 SMART x Laser, TPD7 Premium and all press models in the Energy Saver version. A corresponding quick coupler is always recommended.

100 oval buttons 45mm x 69mm with bottle opener

100 oval button blanks 45mm x 69mm as bottle openers. The blank consists of an upper shell, a transparent film in the appropriate diameter and a bottle opener insert on the back. The buttons are compatible with Secabo Badge Making Machines. We cannot accept any liability for use with other presses and returns are excluded.100 oval button blanks 45mm x 69mmBottle opener functionBlank consists of an upper shell, a transparent film in the appropriate diameter and a bottle opener insert on the backButtons are compatible with the Badge Making Machines from Secabo

Thermal tape transparent copper - 10mmx30m

Heat-resistant thermal adhesive tape for positioning all transfers on the printed material, residue-free removal, transparent copper 1 roll of 10 mm x 30 m.

Thermal tape transparent copper - 10mmx60m

Heat-resistant thermal adhesive tape for positioning all transfers on the printed material, can be removed without leaving any residue, transparent copper. 1 roll of 10 mm x 60 m.

Thermal tape transparent copper - 12mmx60m

Heat-resistant thermal adhesive tape for positioning all transfers on the printed material, can be removed without leaving any residue, transparent copper. 1 roll of 12 mm x 60 m.

Secabo T120 III

Future-proof, powerful and versatile.The Secabo T120 III offers an ideal combination of high cutting width, reliable technology and intelligent workflow integration. With a cutting width of up to 120 cm, it is ideal for processing medium to large media rolls - whether in textile printing, advertising technology or labelling.The integrated optical register mark recognition ensures precise contour cuts. Jobs can be assigned automatically via the QR code system - particularly practical for changing jobs or series production. Thanks to the DrawCut PRO software and direct connection to CorelDraw and Adobe Illustrator, the T120 III can be perfectly integrated into modern workflows.Advantages of the Secabo T160 IIIUp to 120 cm cutting width - ideal for many standard rollsCamera-supported register mark recognition for precise contour cutsQR code function for automatic job recognitionDrawCut PRO included - professional software as standardPlugins for CorelDraw & Adobe IllustratorCompatible with Digital Factory, Caldera, Ergosoft, SignCut, Colorgate, FlexiRobust design for long-term production useUpdateable firmware for long-term expandabilityTypical areas of applicationFlex and flock cutting in textile finishingPrint & cut applications (e.g. DTF)Sticker and label productionAdvertising technology, vehicle labelling, signageTechnical highlightsImproved camera technology for more precise detectionFaster work thanks to optimised mechanics and controlsQR code system for the automation of production processesFull integration into common graphics and RIP softwareConclusionThe Secabo T120 III is the perfect choice for businesses looking for professional cutting quality, smart integration and reliable technology in a flexible format.

Secabo T160 III

Future-proof cutting solution with maximum flexibility.The Secabo T160 III is the perfect solution for large-format cutting applications in advertising technology, textile finishing and industrial production. With a maximum cutting width of 160 cm, it also processes wide media rolls reliably and precisely.The advanced optical register mark recognition, the integrated QR code system and the DrawCut PRO software as standard make the T160 III a powerful, professional cutting solution for modern workflows.Advantages of the Secabo T160 IIIQaptur system: state-of-the-art register mark recognition for precise contour cutsCutting width up to 160 cm - ideal for large formats and roll materialCamera-supported mark recognition for precise contour cutsAutomatic job recognition via QR codeDrawCut PRO included - professional software at no extra costCan be integrated directly into CorelDraw & Adobe Illustrator (plugin)Compatible with Digital Factory, Caldera, Colorgate, Ergosoft, Flexi, SignCutRobust design for continuous useFirmware updates ensure long-term functional expansionTypical areas of applicationLarge-format textile and flex cutsDTF transfer production in large quantitiesPrint & cut workflowsVehicle labelling, advertising technology, label productionTechnical highlightsImproved camera technology for more precise recognitionFaster work thanks to optimised mechanics and control systemQR code system for the automation of production processesFull integration into common graphics and RIP softwareConclusionThe Secabo T160 III is the ideal solution for companies looking for a precise, fast and future-proof cutting solution. With state-of-the-art recognition technology, intelligent software integration and high processing speed, this plotter is perfect for anyone who wants to organise their production processes efficiently.

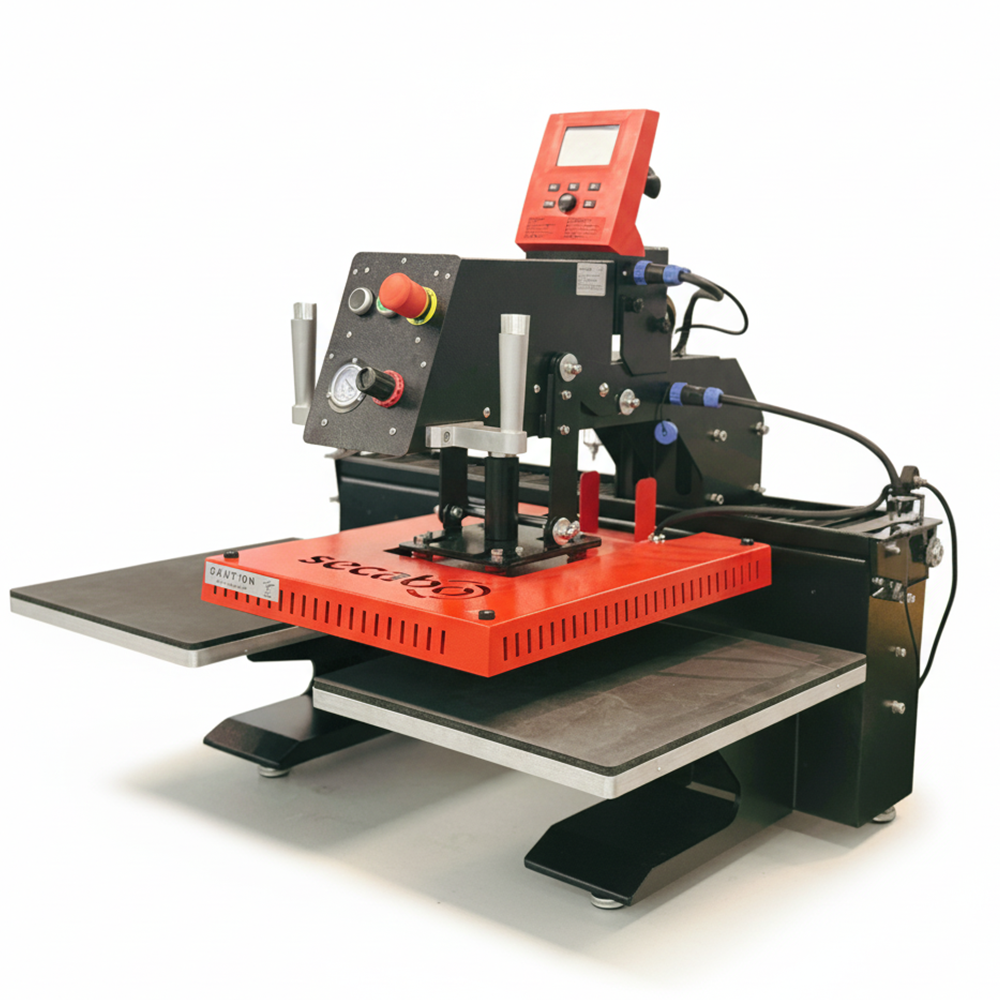

Secabo TPD7 SMART

Maximum efficiency and ease of use - without compromise.The Secabo TPD7 Smart is a high-performance double plate Heat Press with pneumatic control and digital smart control via Bluetooth. It has been specially developed for professional applications with high volumes - from DTF transfers and sublimation to flex and flock applications.The two work plates allow the printing and preparation processes to run in parallel. The TPD7 Smart therefore offers a continuous workflow with significantly increased productivity - ideal for high-throughput production environments.Modularity that pays offThe modular design of the TPD7 Smart offers clear advantages: Components such as the heating plate, base plate or controller can be easily replaced or extended as required. Accessories such as the thermobase or the quick-change system make the press customisable for a wide range of applications. This concept enables investment security, fast maintenance and lower storage costs.Intelligent control for efficient processesThe Secabo Smart App is conveniently controlled via Bluetooth. This allows you to manage temperature, time and pressure digitally and save recurring jobs as presets. This optimises your workflow and reduces sources of error.Advantages of the Secabo TPD7 Smart Pneumatic double plate press for efficient work in series productionSmart app control via Bluetooth for precise control of temperature and timeModular design - compatible with exchangeable plates, Energy Saver Kit, Thermobase and moreGenerous working area - also suitable for bulky textilesRobust construction with encapsulated guidesTwo-hand safety operation for maximum work safetyIdeal for DTF, flex, flock and sublimationTypical areas of applicationDTF transfer productionTextile finishing with flex or flock foilsSublimation on textiles, bags and moreSeries production of workwear, sportswear and merchandise itemsConclusionThe Secabo TPD7 Smart is the perfect solution for professional users looking for maximum productivity, convenience and flexibility - without any laser positioning, but with full power.

Premium ceramic cup, 11 oz, 3 boxes of 36 = 108 cups

High-quality sublimation mug, bright white, with Orca coating, dishwasher-safe. 36 pieces / carton- Suitable for sublimation printing - perfect colour reproduction and razor-sharp motifs.Ideal for personalised photo gifts, merchandising, company logos or advertising motifs.- Dishwasher-safe - long-lasting prints even with frequent cleaning- All-round printing possible - motifs can be positioned flexibly for right and left-handers- Full-surface printing possible - maximum creative design freedom

Ceramic cup Eco, 11 oz, 3 boxes of 36 = 108 cups

High-quality sublimation mug, classic white, with SunCoating, dishwasher-safe. 36 pieces / carton- Suitable for sublimation printing - perfect colour reproduction and razor-sharp motifs.Ideal for personalised photo gifts, merchandising, company logos or advertising motifs.- Dishwasher-safe - long-lasting prints even with frequent cleaning- All-round printing possible - motifs can be positioned flexibly for right and left-handers- Full-surface printing possible - maximum creative design freedom

Secabo TD7 SMART

Secabo TD7 SmartProfessional textile finishing made easy.The Secabo TD7 Smart is a robust, high-performance double platen press that has been specially designed for medium production volumes.Thanks to the integrated Smart Controller, the press can be conveniently controlled via Bluetooth and the free Secabo app - for maximum control, overview and efficiency in day-to-day work.The manual double platen technology enables seamless work in alternating operation: while pressing is taking place on one side, preparation can already be carried out on the other. This saves time and increases productivity - ideal for DTF, flex, flock and sublimation. Advantages of the Secabo TD7 Smart at a glance Two work plates for parallel work - no downtime Bluetooth Smart control via app (Android) Modular design: Compatible with Thermobase, Energy Saver Kit, exchangeable plates and more Large working area also suitable for thick textiles Encapsulated guides for minimum maintenance and maximum service life Typical areas of application DTF transfers in medium runs Textile finishing with flex and flock foils Sublimation on shirts, bags, hoodies Productions with regular job changes Conclusion The TD7 Smart is the perfect solution for anyone looking for an efficient, modular double plate press with intelligent control - powerful in use, flexible in the system.

5 drag knives 30° for Vulcan

5 drag knives for the flatbed cutting plotters of the Vulcan series, cutting angle 30°.

5 drag knives 60° for Vulcan

5 drag knives for the flatbed cutting plotters of the Vulcan series, cutting angle 60°.

Secabo Triple Mug Deal: 3x TM2 Mug Press + Sublite Cups and Sublipaper

This attractive bundle offers everything you need for the perfect start to cup finishing: The Secabo Mug Press TM2 impresses with its simple operation, precise temperature and time control as well as reliable results - ideal for sublimation on ceramic mugs. The Secabo SunGlow sublimation paper in A4 format shines with its fast drying time and outstanding colour transferability. The Orca-Coating premium mugs (11 oz) are ideal for personalised photo gifts, merchandising, company logos or advertising motifs.This bundle contains the following items:- 3x Secabo Mug Press TM2- 3x 36 Orca-Coating premium cups 3x 100 sheets of sublimation paper Secabo SunGlow A4- 3x 100 sheets of sublimation paper Secabo SunGlow A4- 1x heating element for small conical cups