Secabo machines - Professional technology for textile finishing, advertising technology and creative productions

Secabo machines have stood for high quality, precision and reliability in textile finishing and advertising technology for years. Heat Presses, cutting plotters or Badge Making Machines - Secabo provides professionals and beginners with powerful tools to create customised products efficiently and to a high standard.

Our devices are used wherever precise processing, flexible applications and durable technology are required - e.g. in T-shirt printing, film labelling, advertising material production or sublimation printing.

Filter products

Secabo TC1 Heat Press 15cm x 15cm

The TC1 Heat Press from Secabo has a working area of 15 x 15 cm. This makes it perfect for textile finishing, e.g. for emblems, patches, iron-on transfers, branding or product labelling. The TC1 is lightweight and very compact, making it ideal for mobile use at events. Our "little one" is also an inexpensive entry-level model. The TC1 masters transfers on hard-to-reach areas, it presses specifically where it is desired and necessary. This prevents resublimation and dye migration in particular. The plate heats up quickly and has low energy consumption. As you would expect from Secabo, the TC1 is easy to operate, even for beginners. The large opening angle makes it easy to prepare the transfer objects on the base plate. The time and temperature for the transfer can be precisely preselected on the digital controller. The contact pressure is set using the handwheel. Closing the pressing lever starts the pressing process.

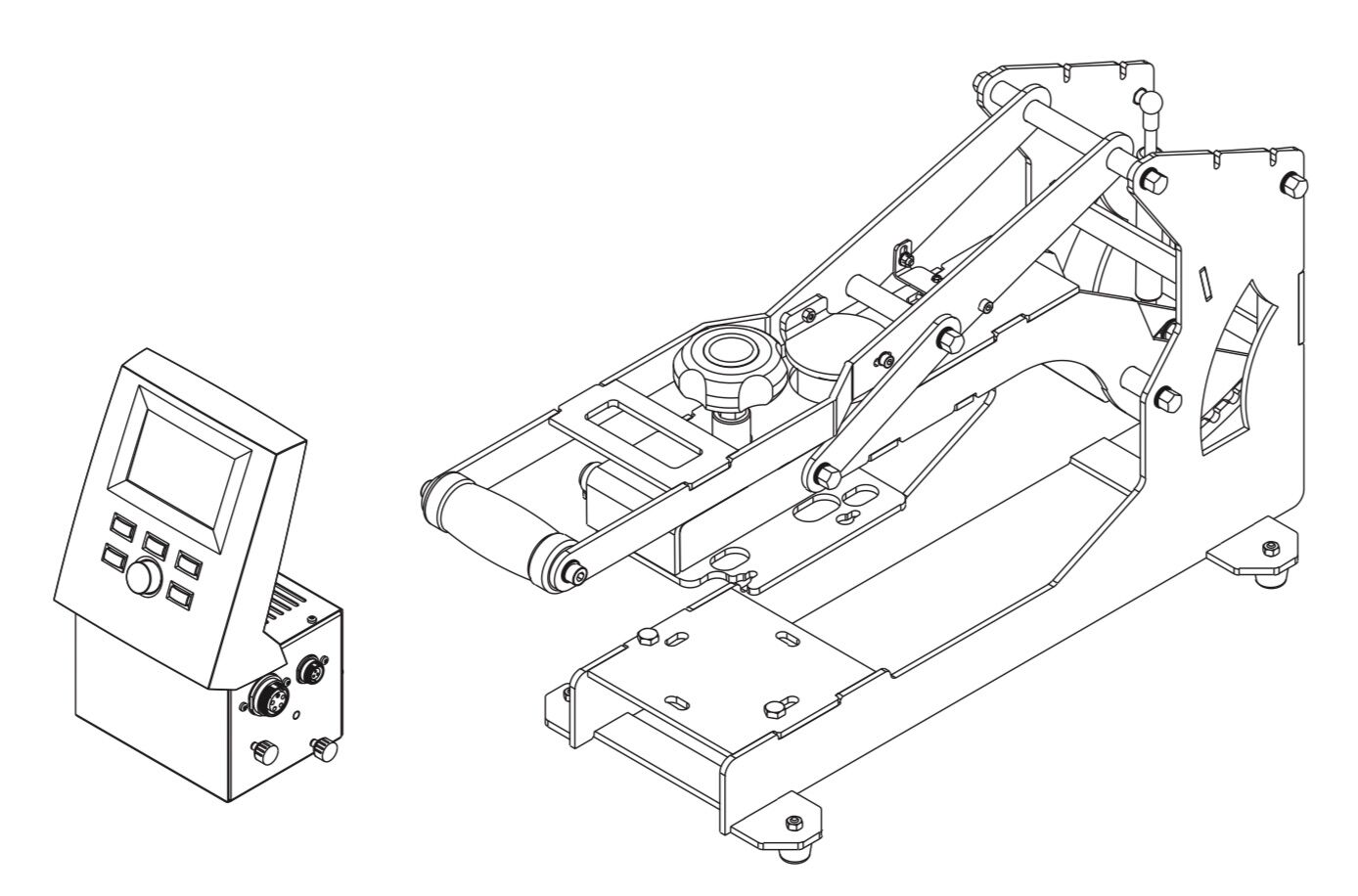

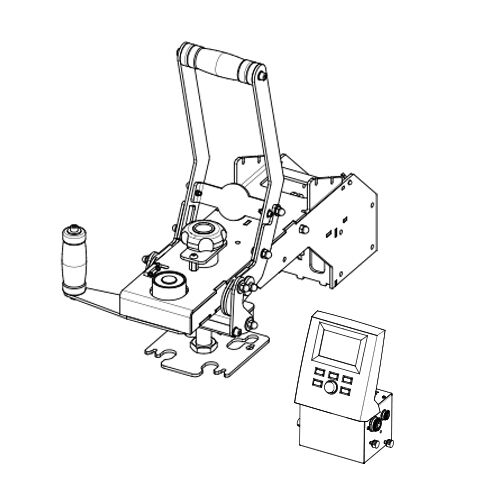

Secabo HPC01 and base TC5 SMART and TC7 SMART

Set consisting of Secabo HPC01 controller and the mechanical base for TC5 SMART and TC7 SMART.

Secabo TC2 Heat Press 23cm x 33cm

With the TC2, Secabo has the right Heat Press for getting started in textile finishing and other transfer techniques. The time and temperature of the transfer can be preselected on the digital controller of the Secabo TC2. An acoustic signal sounds when the set time has elapsed. The contact pressure is set using a handwheel on the top of the heating plate. The pressing process is started by closing the pressing lever. The large opening angle allows convenient preparation of the transfer objects on the base plate. The TC2 has a working surface of 23cm x 33cm and a heating plate with a power consumption of 1,000W.

Secabo TC5 SMART modular Heat Press 38cm x 38cm with Bluetooth

Secabo's new TC5 SMART Heat Press opens up innovative ways to achieve even better performance. This new development of the successful Secabo TC5 automatic toggle press brings a world first to the market, opening up a wide range of new possibilities for users: For the first time, the controller of the TC5 SMART is equipped with a Bluetooth interface which, with the free Secabo Smart Transfer app, allows the press to be controlled while simultaneously accessing a comprehensive function database. For the user, this means: simply enter the fabric type and transfer material and the appropriate combinations for temperature, time and pressure can be called up. Additional functions such as the calculation of heat-up times and warning functions make the app a valuable aid for all common heat transfer processes. The new Secabo TC5 SMART Heat Press offers a working area of 38 cm x 38 cm, is easy to operate and robust during operation. The modular design allows quick and easy installation of interchangeable plates in various formats, quick-change system and slide extension.

Secabo TC5 SMART MEMBRAN modular Heat Press 38cm x 38cm with Bluetooth

This new development of the successful Secabo TC5 MEMBRAN automatic toggle press brings a world first to the market, opening up a wide range of new possibilities for users: For the first time, the controller of the TC5 SMART MEMBRAN is equipped with a Bluetooth interface which, with the free Secabo Smart Transfer app, allows the press to be controlled with simultaneous access to a comprehensive function database. For the user, this means: simply enter the fabric type and transfer material and the appropriate combinations for temperature, time and pressure can be called up. Additional functions such as the calculation of heat-up times and warning functions make the app a valuable aid for all common heat transfer processes. The new Secabo TC5 SMART MEMBRAN Heat Press offers a work surface of 38 cm x 38 cm, is easy to operate and robust during operation. The base plate of the Heat Press has a passive membrane. It opens up many new application possibilities - especially for transfer objects with large differences in height and unevenness. The membrane can be easily inflated using a small blower ball. This allows the user to determine the maximum levelling height of the membrane for a transfer. The contact pressure can be adjusted using a large handwheel at the top of the heating plate. When the Heat Press is closed, a pressure gauge reliably indicates the current contact pressure - in grams per square centimetre. During the pressing process, additional fine adjustment is possible via the blower ball and a release valve. With the TC5 SMART MEMBRAN, not only can the actual transfer pressure be read off, but it can also be set reproducibly time and time again. The modular design allows quick and easy installation of exchangeable plates in various formats, quick-change system and slide extension. A conventional base plate is included in the scope of delivery alongside the membrane plate.

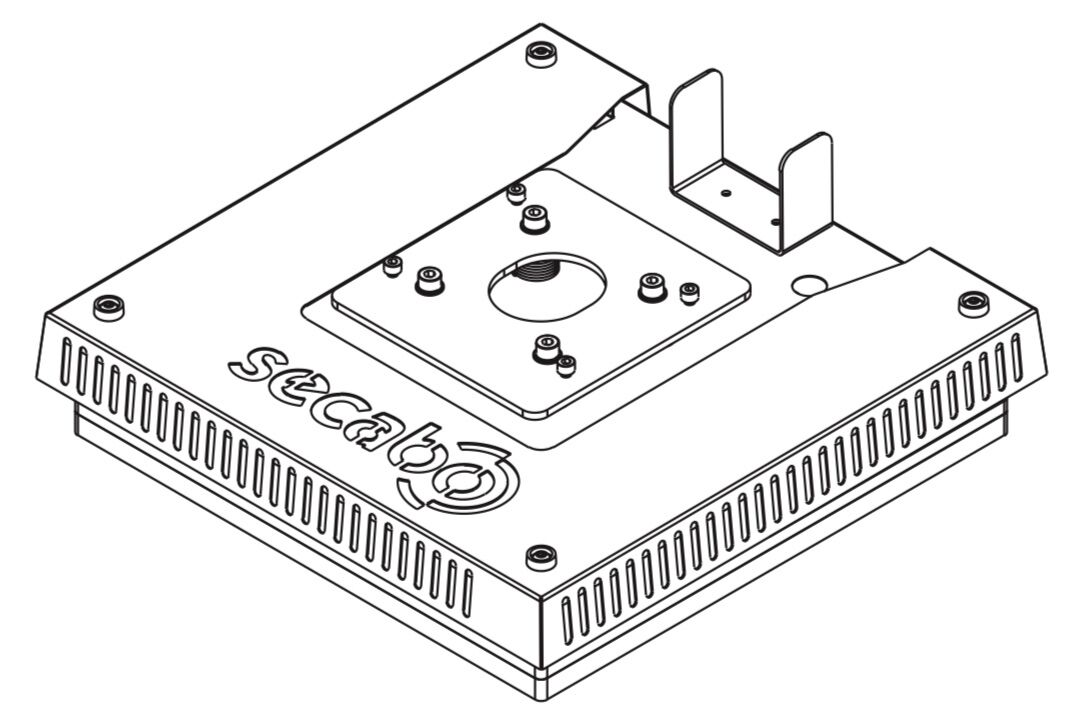

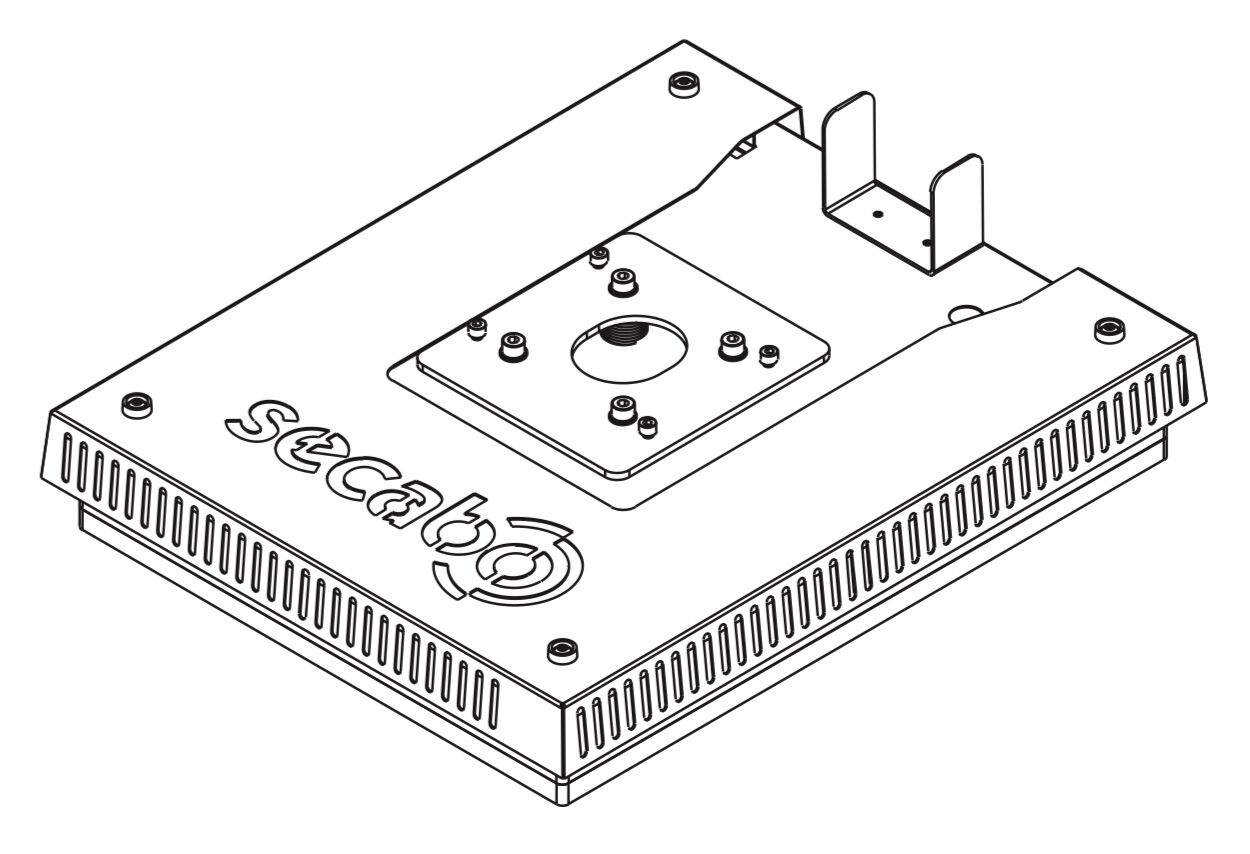

Secabo HP5 heating plate and base plate 38cm x 38cm

Set consisting of heating plate and base plate ready for connection to TC5 SMART.

Secabo TC7 SMART modular Heat Press 40cm x 50cm with Bluetooth

Secabo's new TC7 SMART Heat Press opens up innovative ways to achieve even better performance. This new development of the successful Secabo TC7 automatic toggle press brings a world first to the market, opening up a wide range of new possibilities for users: For the first time, the controller of the TC7 SMART is equipped with a Bluetooth interface which, with the free Secabo Smart Transfer app, allows the press to be controlled while simultaneously accessing a comprehensive function database. For the user, this means: simply enter the fabric type and transfer material and the appropriate combinations for temperature, time and pressure can be called up. Additional functions such as the calculation of heat-up times and warning functions make the app a valuable aid for all common heat transfer processes. The new Secabo TC7 SMART Heat Press offers a working area of 40 cm x 50 cm, is easy to operate and robust during operation. The modular design allows quick and easy installation of interchangeable plates in various formats, quick-change system and slide extension.

Secabo TC7 SMART MEMBRAN modular Heat Press 40cm x 50cm with Bluetooth

This new development of the successful Secabo TC7 MEMBRAN automatic toggle press brings a world first to the market, opening up a wide range of new possibilities for users: For the first time, the controller of the TC7 SMART MEMBRAN is equipped with a Bluetooth interface which, with the free Secabo Smart Transfer app, allows the press to be controlled with simultaneous access to a comprehensive function database. For the user, this means: simply enter the fabric type and transfer material and the appropriate combinations for temperature, time and pressure can be called up. Additional functions such as the calculation of heat-up times and warning functions make the app a valuable aid for all common heat transfer processes. The new Secabo TC7 SMART MEMBRAN Heat Press offers a work surface of 40 cm x 50 cm, is easy to operate and robust during operation. The base plate of the Heat Press has a passive membrane. It opens up many new application possibilities - especially for transfer objects with large differences in height and unevenness. The membrane can be easily inflated using a small blower ball. This allows the user to determine the maximum levelling height of the membrane for a transfer. The contact pressure can be adjusted using a large handwheel at the top of the heating plate. When the Heat Press is closed, a pressure gauge reliably indicates the current contact pressure - in grams per square centimetre. During the pressing process, additional fine adjustment is possible via the blower ball and a release valve. With the TC7 SMART MEMBRAN, not only can the actual transfer pressure be read off, but it can also be repeatedly and reproducibly adjusted. The modular design allows quick and easy installation of exchangeable plates in various formats, quick-change system and slide extension. A conventional base plate is included in the scope of delivery alongside the membrane plate.

Secabo TC7 LITE modular Heat Press 40cm x 50cm

Best performance and high convenience with the Secabo LITE series - With this new development of the successful Secabo TC7 toggle press, Secabo is launching a lucrative modular system on the market that opens up a wide range of new possibilities for users. A plus in flexibility thanks to easily interchangeable components, in short a basic product with great upgrade options. The new LITE models therefore have the advantage of being able to retrofit individual base plates or heating platens at low cost and easily replace components as required. The TC7 LITE Heat Press from Secabo is a modular, automatically opening toggle press. The user does not have to wait next to the press during transfers, but can carry out other activities. Once the set time has elapsed, the press opens automatically and announces this three seconds in advance with an acoustic signal. The pressing process can be interrupted at any time at the touch of a button - for example to pre-press textiles. The temperature and pressing time are conveniently preselected using a digital controller. The contact pressure is set using a large handwheel on the top of the heating plate. The TC7 LITE Heat Press, with a working surface of 40cm x 50cm, has an additional cover plate on the heating plate to protect the user from burns. The design of the TC7 LITE is fully modular; the control unit, heating plate, base plate and base frame can be removed and replaced in a few simple steps. This also allows the use of other heating plates, for example. The LITE Heat Presses offer everything that makes textile transfers with Secabo so convenient. All professional applications of common heat transfer processes such as flock foils, flex foils, sublimation, inkjet flex, etc. are of course possible. The Secabo TC7 LITE can be optionally equipped with interchangeable plates in various formats - including a membrane base plate, a quick-change system and a slide extension for use as a double plate press. You also have the option of upgrading the TC7 LITE to our Secabo TC-SMART series.

Secabo HP7 heating plate and base plate 40cm x 50cm

Set consisting of heating plate and base plate ready for connection to TC7 SMART.

Secabo TP10 pneumatic Heat Press 80cm x 100cm

The newly developed TP10 from Secabo is the ideal Heat Press for professional finishers of large-format objects in particular: With an extra large work surface of 80cm x 100cm, this heat press model can be used to carry out heat transfers on large-format substrates such as flags, bed linen or textile room dividers. The base plate acts as a drawer element, which makes it easy to arrange the transfer objects and can be handled with little effort despite its size. The contact pressure of the TP10 Heat Press is generated with compressed air, which means easy working with consistent and reproducible results. The pneumatic heating platen head allows for error-free transferring of a wide variety of materials without offset effects or similar due to the vertical contact pressure. The Secabo TP10 Heat Press with a heating capacity of 5.1 kW is suitable for all known heat transfer processes and can therefore be used in almost all areas of transfer technology.

Secabo TS7 SMART Manual head

Set consisting of HPC01 controller and TS7 SMART manual head.

Secabo THE BEAST

The absolute professional device for high-end applications at the highest levelTHE BEAST from Secabo combines a newly developed smart Heat Press with a heated lower plate.TS7 SMART - the centrepiece of THE BEAST is the first Heat Press from Secabo "Made in Germany".THE BEAST enables high-end applications and gentle textile transfers.Thanks to its modular design, the newly developed Secabo TS7 SMART Heat Press in combination with the Thermobase TB7 can master even the most demanding textile finishing tasks. The combination product "THE BEAST" works quickly, is gentle on textiles and solves typical transfer problems.Textile finishing at the cutting edge The TS7 SMART swingaway heat press from Secabo brings textile finishing up to date: it is a high-performance, efficient press. It processes large prints with a working area of 40 x 50 cm and creates transfer objects up to seven centimetres high.The new TS7 SMART can also be controlled using the Secabo app. This has the most comprehensive database of transfer parameters currently available on the market: the user selects the fabric type and transfer medium and automatically receives the appropriate settings for temperature, time and pressure. Another major advantage of the Secabo app is the simple instructions for complex multi-stage transfer processes.New heating technology for transfers With the new Thermobase TB7, Secabo also offers a heated lower plate as an extension. This is particularly recommended for sensitive textiles. It also ensures reliable white toner transfers and sublimation transfers. When using the Thermobase, the heat also comes from below. This enables lower overall transfer temperatures, shorter transfer times and reduces marks on the textiles.As you would expect from Secabo, THE BEAST is easy to use, even for beginners. THE BEAST is compatible with quick-change systems, exchangeable plates and the slide extension as well as other Secabo accessories.Secabo Heat Press TS7 SMART:Bluetooth interface for Secabo SMART Transfer App with its own transfer database and numerous additional featuresDigital controller for temperature, time, pre-pressing, counting function and many other features with innovative operating conceptVery large swivelling angle 110°Suitable for transfer objects from 0 mm - 70 mm in heightMax. Contact pressure of 250g/cm² achievable with low manual forceLeft/right swivelling direction selectableCompatible with quick coupler and slideModular design, compatible with various heating and base platesSecabo Thermobase TB7 40cm x 50cm:The temperature of the TB7 is regulated with its own Secabo controllerHeated base plate as an extension for your 40cm x 50cm Secabo models, such as TC7 SMART, TS7 SMART, TPD7 and TPD7 PREMIUM.Particularly suitable for delicate textilesEasy to fit, also on quick coupler and slide extensionHeats up quickly to a temperature of 160 °CLow power consumptionFor retrofitting many old and almost all new Secabo Heat PressesSecabo quick-change plate changer for LITE and SMART seriesUp to three interchangeable plates can be mounted next to each other (interchangeable plates must be ordered separately)Exchangeable plates can be changed within a few secondsThe scope of delivery includes an adapter for mounting the original base plate on the quick coupler

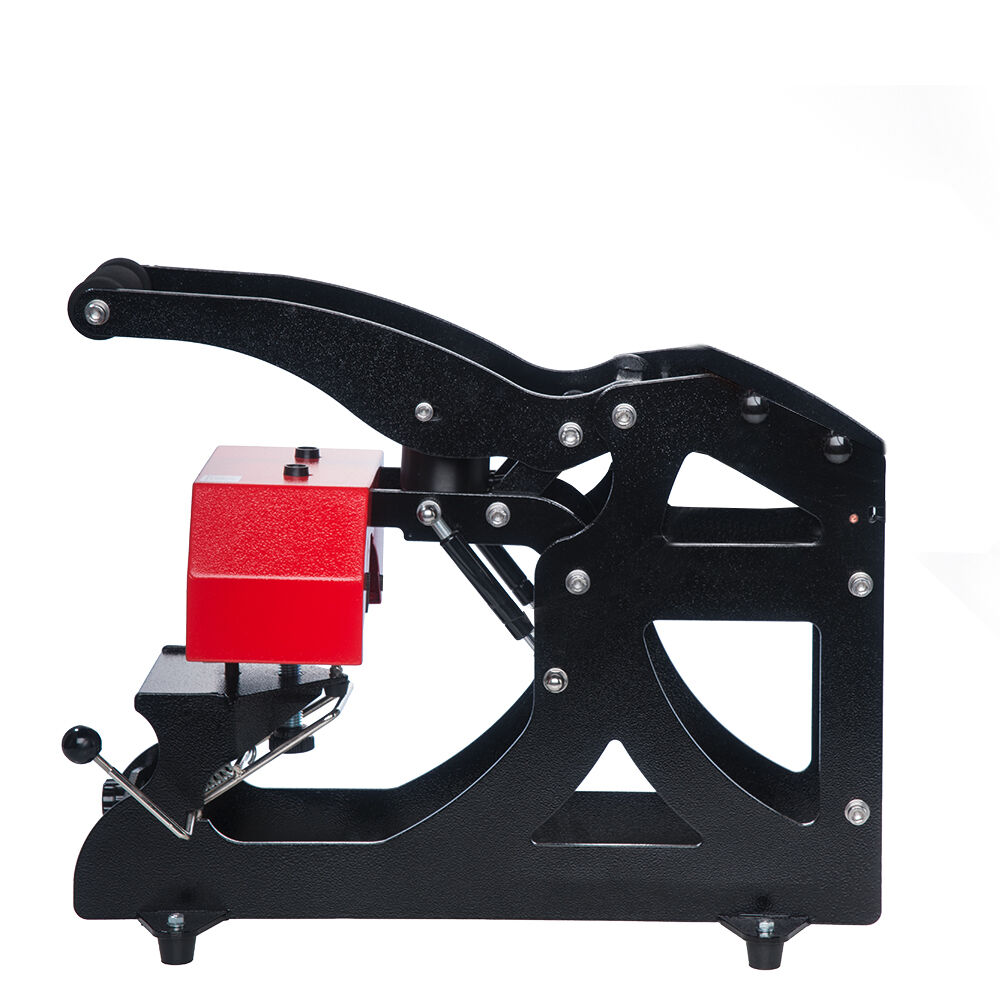

Secabo TCC SMART automatic cap press

With the new TCC SMART cap press, Secabo is opening up innovative paths and thus even better performance in the finishing of baseball caps, hats and similar products. The controller of the TCC SMART is equipped with a Bluetooth interface that allows the press to be controlled with the free Secabo SMART Transfer app while at the same time providing access to a comprehensive function database. For the user, this means: simply enter the fabric type and transfer material and the appropriate combinations for temperature, time and pressure can be called up. Additional functions such as the calculation of heat-up times and warning functions make the app a valuable aid for all common heat transfer processes. The contact pressure of the new Secabo TCC SMART heat press for caps is set using a handwheel on the underside of the easily interchangeable base elements, and a fitted cap is clamped from below using a clamp. The automatically opening TCC SMART has a large opening angle and a button for manual opening before the set time has elapsed. It is suitable for the professional use of all common heat transfer processes such as flock foils, flex foils, sublimation, transfer, inkjet flex, etc.

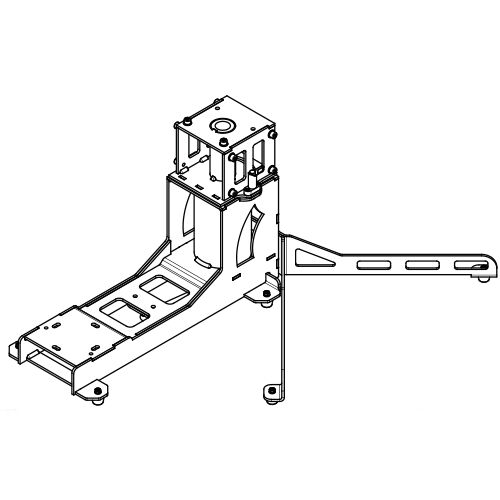

Base element for Secabo and TCC SMART TCC 7.0cm x 16.5cm

Interchangeable base element for the Secabo TCC and TCC SMART cap press. With the base elements in different sizes, even particularly small or particularly large caps and hats can be processed perfectly in the press.

Base element for Secabo TCC and TCC SMART 7.6cm x 14.6cm

Interchangeable base element for the Secabo TCC and TCC SMART cap press. With the base elements in different sizes, even particularly small or particularly large caps and hats can be processed perfectly in the press.

Base element for Secabo TCC and TCC SMART 10.2cm x 16.5cm

Interchangeable base element for the Secabo TCC and TCC SMART cap press. With the base elements in different sizes, even particularly small or particularly large caps and hats can be processed perfectly in the press.

Base element for Secabo TCC and TCC SMART 10.2cm x 20.3cm

Interchangeable base element for the Secabo TCC and TCC SMART cap press. With the base elements in different sizes, even particularly small or particularly large caps and hats can be processed perfectly in the press.

Secabo TM1 Mug Press

The TM1 Mug Press from Secabo is ideal for conveniently carrying out sublimation transfers on ceramic mugs and similar objects. The Secabo TM1 Heat Press is suitable for both beginners and professional users and is quick and safe to operate thanks to its digital controller. The contact pressure can be easily adjusted using a handwheel. Three different heating elements are optionally available - also in a conical design. The Secabo TM1 Mug Press is supplied with a heating sleeve for cups with a diameter of 75-90 mm (heating elements are wearing parts). We also recommend only switching on the Mug Press for actual use and not heating it continuously.

Heating element for Secabo TM1, TM2 and TM5 60mm-75mm (A-grade)

Heating element for cups with a diameter of 60mm to 75mm. Suitable for the Secabo TM1, TM2 and TM5 Mug Press. Safety plug connector and hand screws for quick and easy changing of the heating sleeves. (A-Grade)

Heating element for TM1 and TM2 for conical cups (A-grade)

Heating element for conical cups with an upper diameter of approx. 90mm and a volume of approx. 350ml. Suitable for the Secabo TM1 and TM2 Mug Press. Safety plug connector and hand screws for quick and easy changing of the heating sleeves. (A-Grade)

Heating element for Secabo TM1, TM2 and TM5 75mm-90mm (A-grade)

Heating element for cups with a diameter of 75mm to 90mm. Suitable for the Secabo TM1, TM2 and TM5 Mug Press. Safety plug connector and hand screws for quick and easy changing of the heating sleeves. (A-Grade)