Secabo machines - Professional technology for textile finishing, advertising technology and creative productions

Secabo machines have stood for high quality, precision and reliability in textile finishing and advertising technology for years. Heat Presses, cutting plotters or Badge Making Machines - Secabo provides professionals and beginners with powerful tools to create customised products efficiently and to a high standard.

Our devices are used wherever precise processing, flexible applications and durable technology are required - e.g. in T-shirt printing, film labelling, advertising material production or sublimation printing.

Filter products

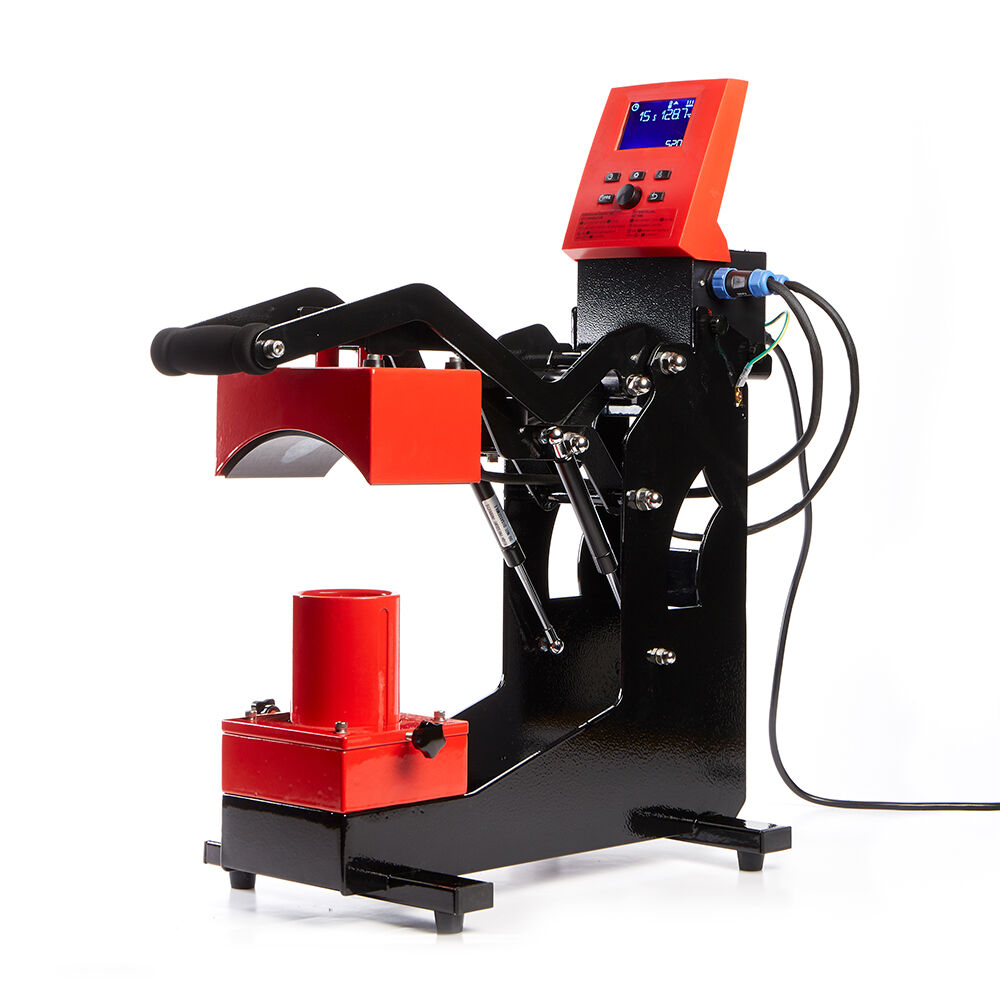

Secabo TM2 Mug Press

The TM2 Mug Press from Secabo has an extra-wide heating element that allows you to print 2 mugs at the same time - or a jug or large mug up to 21 cm high. Whether you are a beginner or a professional - with the TM2, sublimation transfers on ceramic cups and similar objects are particularly efficient. The digital controller controls the temperature and time precisely and reliably. The contact pressure can be easily adjusted using a handwheel. The device is supplied with a sleeve for 325 ml cups. Six additional heating elements in various sizes are optionally available, including for conical cups. Our recommendation: Only switch on the Heat Press for actual use, as this protects the heating element and saves energy.

Heating element for Secabo TM2 for 2 cups, 7.5 - 9.0cm Grade A

Heating element for two cups with a capacity of 325ml each. Suitable for the Secabo TM2 Mug Press. Safety plug connector and hand screws for quick and easy changing of the heating sleeves. Total width of the heating element: 220-230mm.

Heating element for Secabo TM2 for conical shot glasses, 3.5/5cm - 4.5/6cm

Heating element for very small conical cups with a capacity of 40ml. Suitable for the Secabo TM2 Mug Press. Safety plug connector and hand screws for quick and easy changing of the heating sleeves.

Heating element for Secabo TM2 for espresso cups, 4.5cm - 5.5cm

Heating element for small cups with a capacity of 70ml. Suitable for the Secabo TM2 Mug Press. Safety plug connector and hand screws for quick and easy replacement of the heating sleeves.

Heating element for TM2 for large conical cups (A-grade)

Heating element for large conical cups with a capacity of 500ml. Suitable for the Secabo TM2 Mug Press. Safety plug connector and hand screws for quick and easy changing of the heating sleeves.

Secabo TM5 Mug Press

With the TM5 Mug Press from Secabo, orders can be processed faster. It can carry out transfers on up to 5 cups simultaneously, thanks to 5 separately controllable heating elements. This makes the TM5 ideal for efficient sublimation transfers on ceramic cups and similar objects, especially for larger print runs or higher throughput. The digital controllers control the temperature and time of the heating elements precisely and reliably. The contact pressure can be easily adjusted using a handwheel. The appliance is supplied with 5 cuffs for 325 ml cups, with an additional spare cuff included free of charge. An additional heating element for small cups is available as an option. Our recommendation: Only switch on the individual heating elements for actual use, as this protects the heating elements and saves energy.

Secabo TCB SMART ball press

Play in the premier league with the new ball press from Secabo - With the new TCB SMART ball press, Secabo is opening up innovative ways to achieve even better ball finishing performance. This Heat Press enables you to finish most inflatable sports balls, including artificial leather footballs, handballs and basketballs, in just a few simple steps. Even a football can be customised with a logo, player name or number using the Secabo TCB Smart Ball Press. Personalised souvenirs and prizes for events or give-aways can be produced with single or multi-coloured transfers. All balls can be pressed at the same temperature of 113 °C for 8 seconds. The low temperature is important to avoid damaging sensitive plastics or artificial leather. We recommend a transfer size of up to 5 cm x 8 cm so that the foil lies smoothly on the curved surface of the ball. The contact pressure of the new TCB SMART Heat Press for balls from Secabo is adjusted on the underside by pressing the cylinder downwards and adjusting it with the two screws on the left and right. The specially shaped heating plate fits almost all ball sizes and shapes. The adjustable cylinder ensures that the pressure can be adjusted as precisely as possible to the ball size. The automatically opening ball press has a large opening angle and a button for manual opening before the set time has elapsed. It is suitable for the professional use of all common heat transfer processes such as flock foils, flex foils, sublimation, transfer, inkjet flex, etc. The ball press has a digital temperature and time display. Additional functions such as the calculation of heat-up times and warning functions, in combination with the Secabo app, make this a valuable aid for all common heat transfer processes.

Secabo TS7 LITE modular Swing Press 40cm x 50cm

Best performance and high comfort with the Secabo LITE seriesThe Secabo TS7 LITE marks an innovative milestone in the development of swing-away Heat Presses. As part of Secabo's new LITE series, the TS7 LITE offers a cost-effective, high-performance solution for demanding textile finishing and transfer printing projects. With a working area of 40cm x 50cm, it is ideal for larger designs and enables efficient production at the highest quality.The LITE Heat Presses offer everything that makes textile transfers with Secabo so convenient. All professional applications of common heat transfer processes such as flock foils, flex foils, sublimation, DTF transfers, etc. are of course possible. The Secabo TS7 LITE can be optionally equipped with interchangeable plates in various formats - including a membrane base plate, a quick-change system and a slide extension for use as a double plate press.Intelligent display functions: Simple and quick setting of temperature and time via the digital controller.State-of-the-art press design: The TS7 LITE impresses with its intelligent design and the use of high-quality materials. Its modular design enables quick and easy adaptation to different requirements.A basic product with extensive upgrade options: The TS7 LITE offers numerous customisation and upgrade options to create your ideal work tool. From retrofitting with a passive membrane base plate to integrating the Secabo TB7 Thermobase for even more precise transfers - the TS7 LITE adapts to your needs.The Secabo TS7 LITE Heat Press represents a new generation of heat presses that enable efficiency, flexibility and the highest quality in textile finishing. Discover the diverse possibilities of the TS7 Lite and set new standards in your production.Heat Press opens automatically after the time has elapsedDigital controller for temperature and time Temperature and time can be set on the controller using arrow keysModular design, components can be easily exchangedEasily adjustable contact pressureHigh-quality heating plate with additional protective plateSuitable for all common transfer processesCan be retrofitted with accessories such as exchangeable plates, slide extension or membrane heating plate for even greater productivity.

Secabo TCC LITE cap press

With the Secabo LITE series, users get the best performance and maximum convenience when finishing baseball caps, hats and similar products. The innovative TCC LITE cap press enables even better performance thanks to new ways of finishing.Users can pursue other activities during the transfer process as they do not have to wait next to the press. The automatic opening of the press after the set time has elapsed is signalled by an acoustic signal.The temperature and pressing time can be conveniently preselected via the digital controller. The contact pressure is set using a handwheel on the underside of the easily exchangeable base elements. The automatically opening TCC LITE has a large opening angle. In addition, the base elements in various sizes also allow particularly small or particularly large caps and hats to be processed perfectly in the press.The LITE cap presses offer all professional applications of common heat transfer processes such as flock foils, flex foils, sublimation, DTF, etc. With the Secabo LITE series, users get the best performance and maximum convenience when finishing baseball caps, hats and similar products.Easily adjustable contact pressureModular designSuitable for all common transfer processes

Secabo TCB LITE ball press

Play in the premier league with the new ball press from SecaboExperience the best performance and highest comfort with the Secabo TCB LITE ball press - This innovative Heat Press opens up a world of new possibilities and flexibility when customising inflatable sports balls, such as synthetic leather footballs, handballs and basketballs. Personalised mementos and prizes for events or give-aways can be produced with logos, player names or numbers.The automatically opening TCB LITE ball press has a digital temperature and time display and is suitable for all standard heat transfer processes. The specially shaped heating plate fits almost all ball sizes and shapes, while the adjustable cylinder ensures precise pressure. The same temperature of 113 °C for 8 seconds can be applied to all balls to avoid damaging delicate plastics or artificial leather. A transfer size of up to 5 cm x 8 cm is recommended to ensure a smooth application on the curved ball surface.The TCB LITE ball press offers convenience and supports all professional applications of common heat transfer processes such as flock foils, flex foils, sublimation, inkjet flex, etc.Digital controller for temperature and timeAdjustable temperature (max. 220°C) and timeEasily adjustable contact pressureHigh-quality heating plate with additional protective plateSuitable for all common transfer processesSpecially shaped heating plate for almost all ball sizes and shapesAdjustable cylinder for precise pressure on different ball sizesIdeal for producing personalised mementos and prizes for events or giveaways

Silicone mat 30cm x 40cm

Heat-resistant silicone mat for levelling out uneven areas (e.g. on tiles) or for protecting sensitive materials when using a Heat Press, 30cm x 40cm, thickness 1mm

Silicone mat 40cm x 40cm

Heat-resistant silicone mat for levelling out uneven areas (e.g. on tiles) or for protecting sensitive materials when using a Heat Press, 40cm x 40cm, thickness 1mm

Silicone mat 40cm x 50cm

Heat-resistant silicone mat for levelling out uneven areas (e.g. on tiles) or for protecting sensitive materials when using a Heat Press, 40cm x 50cm, thickness 1mm

Silicone mat 40cm x 60cm

Heat-resistant silicone mat for levelling out uneven areas (e.g. on tiles) or for protecting sensitive materials when using a Heat Press, 40cm x 60cm, thickness 1mm

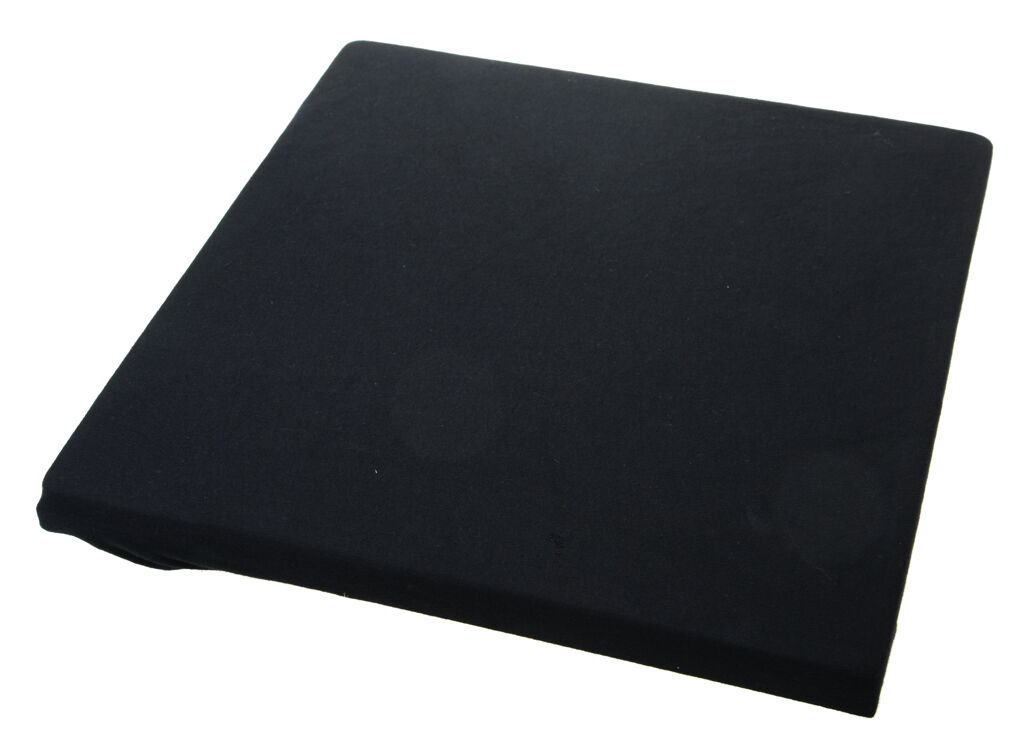

Cover for base plate, 38cm x 38cm

Cover for a Heat Press base plate in 38cm x 38cm format. Heat-resistant up to 220°C. Protects the base plate from discolouration and damage. Cover is washable.

Cover for base plate, 40cm x 50cm

Cover for a Heat Press base plate in 40cm x 50cm format. Heat-resistant up to 220°C. Protects the base plate from discolouration and damage. Cover is washable.

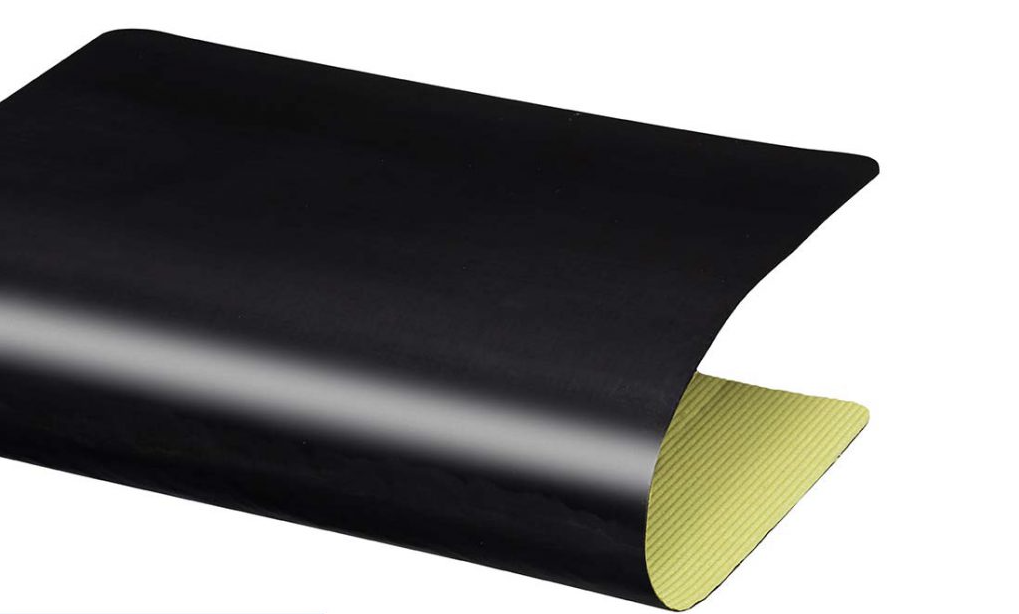

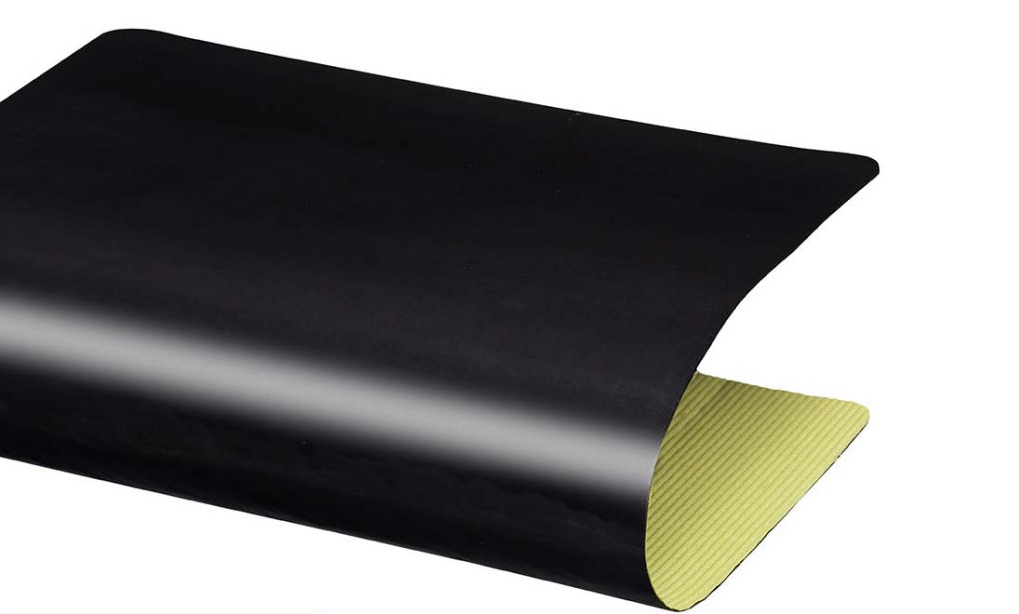

Antistatic heating plate protection, self-adhesive, with PTFE coating 28 x 38 cm

Self-adhesive glass fibre film with PTFE coating. As a replacement for damaged or worn non-stick coatings on Heat Presses, cut to size 28cm x 38cm, suitable for all common Heat Press models from Stahls, Secabo, etc. Thickness 150µm.

Antistatic heating plate protection, self-adhesive, with PTFE coating 38 x 38 cm

Self-adhesive glass fibre film with PTFE coating. As a replacement for damaged or worn non-stick coatings on Heat Presses, cut to size 38cm x 38cm, suitable for all common Heat Press models, thickness 150µm.

Antistatic heating plate protection, self-adhesive, with PTFE coating 40 x 50cm

Self-adhesive glass fibre film with PTFE coating. As a replacement for damaged or worn non-stick coatings on Heat Presses, cut to size 40cm x 50cm, suitable for all common Heat Press models, thickness 150µm.

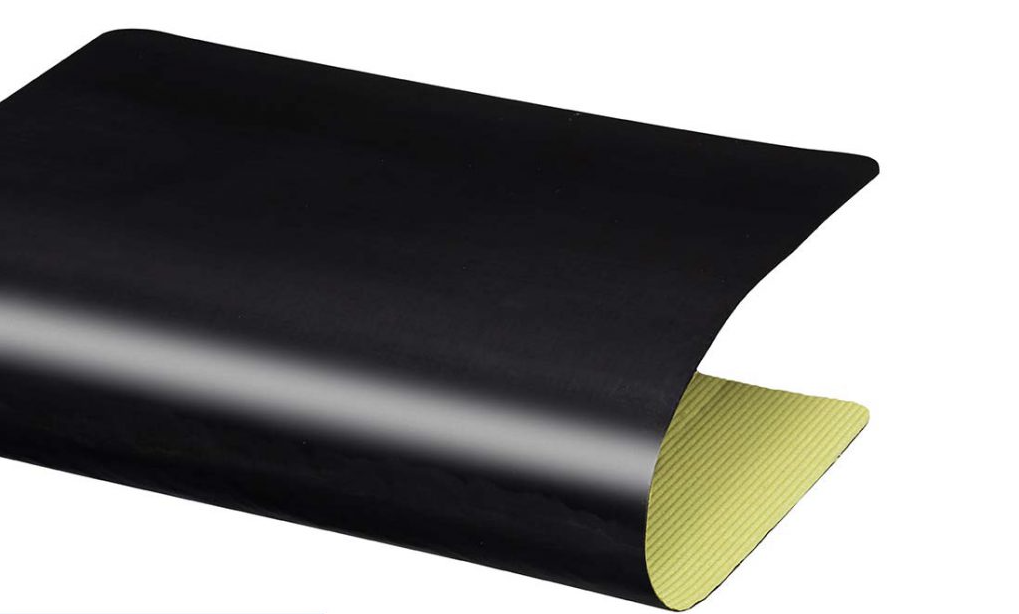

Antistatic protective film for PTFE transfers, 38cm x 50cm

Cover film with PTFE coating. Suitable for protecting transfer objects, for direct printing or for re-pressing in Heat Presses. Cut to size 38cm x 50cm. Suitable for all common Heat Press models, thickness 70µm.

Antistatic protective film for PTFE transfers, 50cm x 60cm

Cover film with PTFE coating. Suitable for protecting transfer objects, for direct printing or for re-pressing in Heat Presses. Cut to size 50cm x 60cm. Suitable for all common Heat Press models, thickness 70µm.

Antistatic protective film for PTFE transfers, 80cm x 100cm

Cover film with PTFE coating. Suitable for protecting transfer objects, for direct printing or for re-pressing in Heat Presses. Cut to size 80cm x 100cm. Suitable for all common Heat Press models, thickness 70µm.

Antistatic protective film for PTFE transfers, 100cm x 120cm

Cover film with PTFE coating. Suitable for protecting transfer objects, for direct printing or for re-pressing in Heat Presses. Cut to size 100cm x 120cm. Suitable for all common Heat Press models, thickness 70µm.

Silicone foam sheet 8cm x 12cm

Silicone foam support for the interchangeable plate 8cm x 2cm for Heat Presses, thickness 10mm.